Model: RD6006/RD6006-W

Input voltage range: 6-70.00V

Output voltage range: 0-60.00V

Output current range: 0-6.000A

Output power range: 0-360W

Input voltage measurement resolution: 0.01V

Output voltagesetting measurement resolution: 0.01V

Output current setting measurement resolution: 0.001A

Battery voltage measurement resolution: 0.01V

Input voltage measurement accuracy: ±(1%+5 digits)

Output voltage accuracy between setting and measurement: ±(0.3%+3 digits)

Output currentaccuracybetween setting and measurement:±(0.5%+5 digits)

Battery voltage measurement accuracy: ±(0.5%+3 digits)

Automatic cut off current valuewhen charging:10mA

Output ripple typical:100mV VPP

Working temperature range: -10℃~40℃

External sensor Temperature detection range:-10℃~100℃/0℉~200℉

External sensor Temperature detection accuracy:±3℃/±6℉

Constant voltage moderesponse time: 2ms(0.1A-5A Load)

Constant voltage mode load regulation: ±(0.1%+2 digits)

Constant current mode load regulation: ±(0.1%+3 digits)

Capacity measurement range: 0-9999.99Ah

Energy measurement range: 0-9999.99Wh

Capacity and energy statistical error: ±2%

Buck working mode: Voltage drop >1V and >10%

Over temperature protection: System temperature>80℃

Screen brightness setting: 0-5(6 level in total)

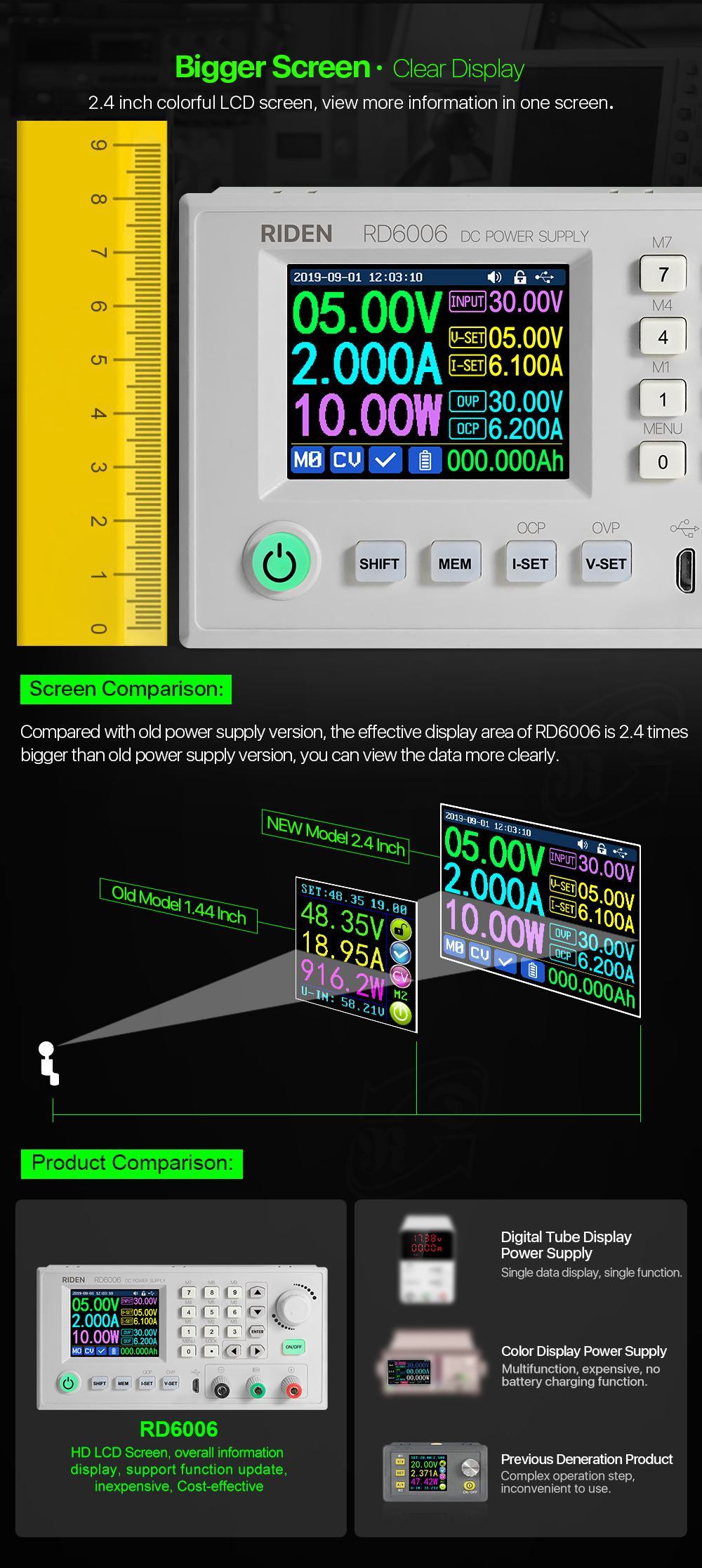

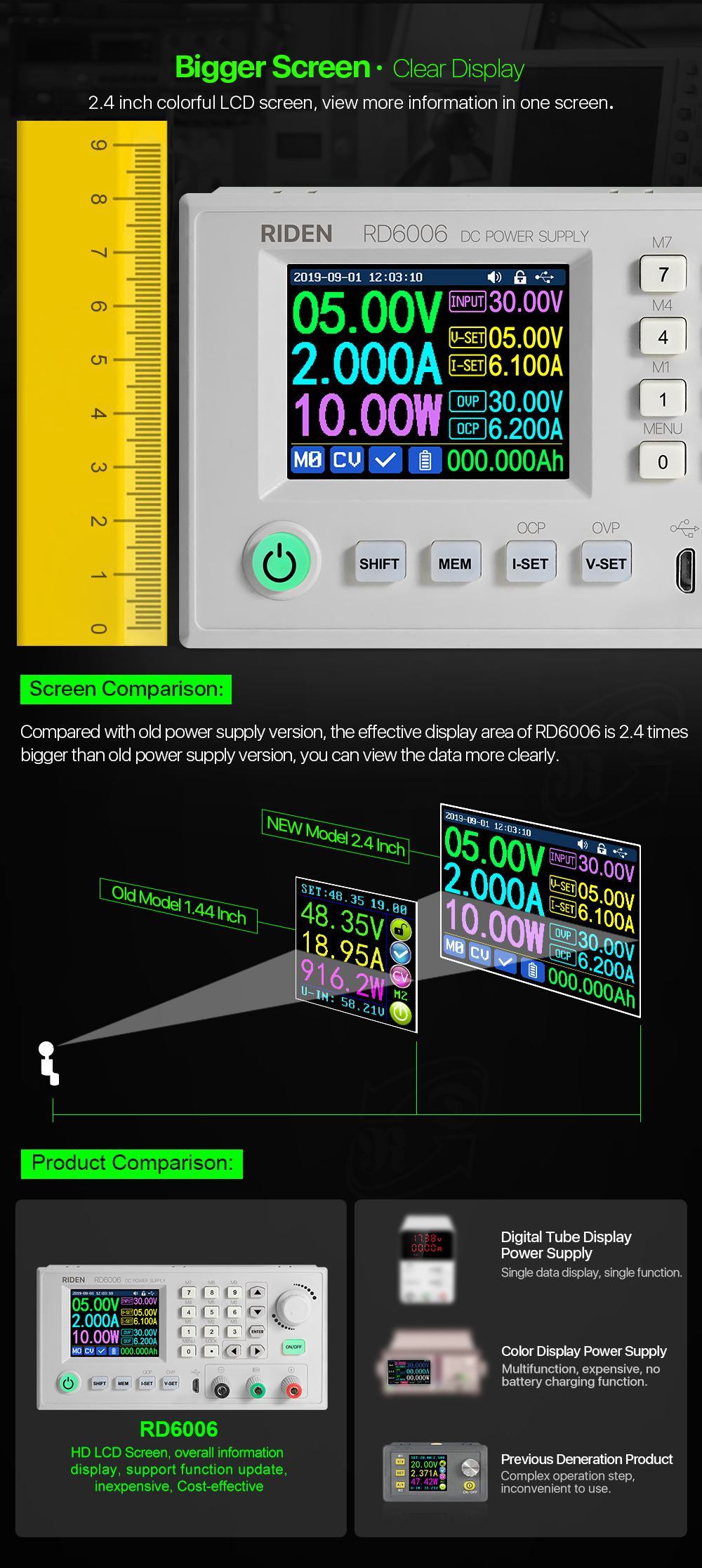

Screen: 2.4inch color HD display

Cooling fan start condition:Output voltage>40V or Output current>4A

or System temperature>45℃

Cooling fan shut down condition:Output voltage<40V and Output current<3.9A

and System temperature<45℃

Weight(with package):About 0.58kg

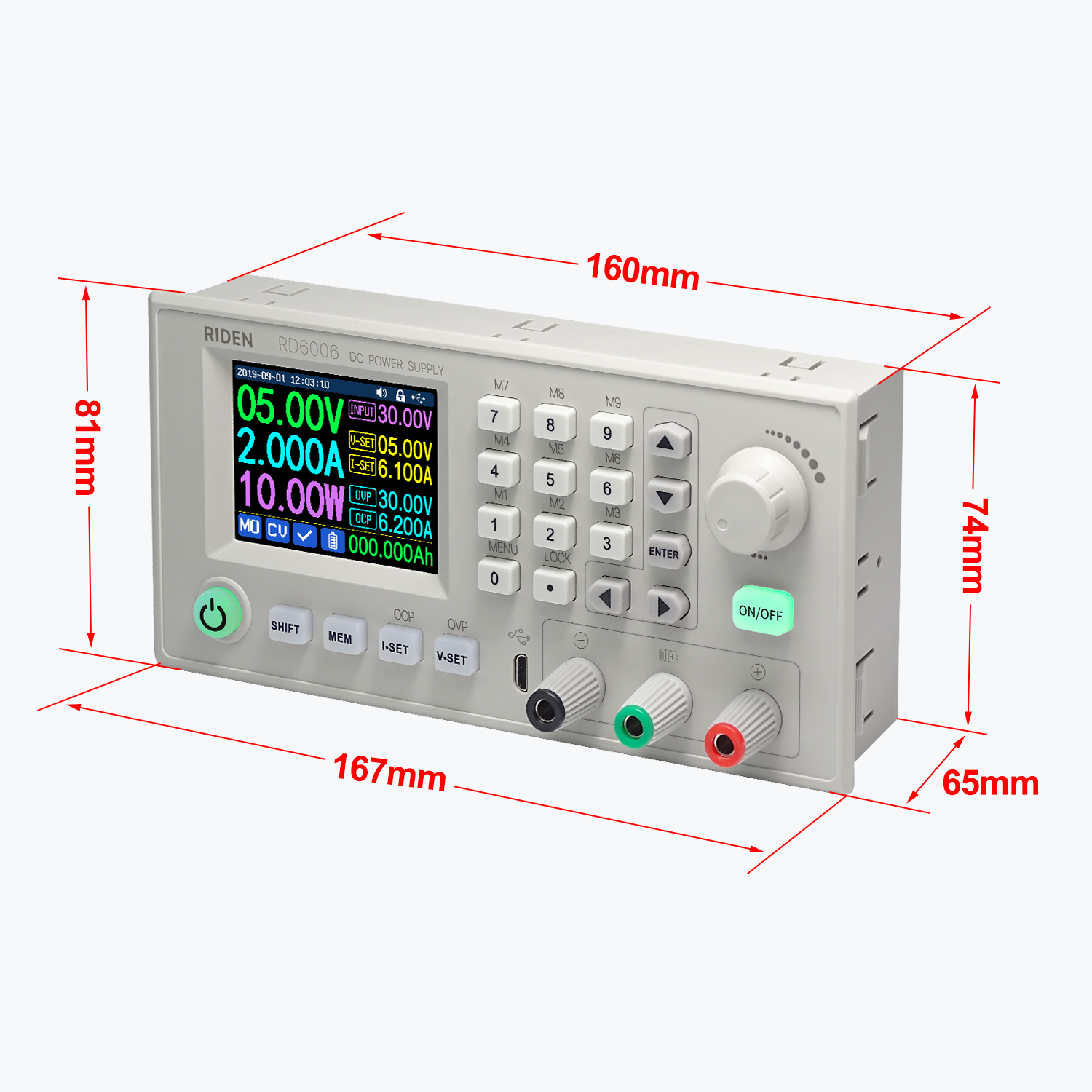

Product dimension: 167*81*65mm

All RD6006/RD6006W instruction and case installation instruction APP and PC software download Link :

1,Instruction video:

a.section 1.4.2.1Battery Charging Function Introduction:https://youtu.be/irTbqfqtgU0

b.section 1.4.2.2Output Voltage and Output Current Setting:https://youtu.be/S6Kan66dNsk

c.section 1.4.2.3Data Group Quick Storage and Call out:https://youtu.be/eo5saPjOGpo

d.section 1.4.2.4Keypad lock and unlock:https://youtu.be/zxpmasJyQ6Y

e.section 1.4.2.5System Setting:https://youtu.be/Q9d3rIgIrOc

f.section 1.4.2.6Main Page Style Setting:https://youtu.be/f51VDiY2VHE

g:section 1.4.2.7Storage Data Setting:https://youtu.be/i1kTeurS13I

h:section 1.4.2.8System Information:https://youtu.be/Um4NQObeeJE

i:section 2.1.2IOS APP Download, Installation and Connection:https://youtu.be/nH2HYwop0TE

j:section 2.4.2IOS APP Operation:https://youtu.be/lXSw1CM9IY8

k:section 3.1.1/3.2.3.2Android APP Download, Installation and Connection:https://youtu.be/QwyBEUCnp9c

l:section 3.2.3.3Anroid APP Operation:https://youtu.be/hqrF4keTfbE

m:section 4.1/4.3.1PC Software Download and basic operation:https://youtu.be/mjt1RMaah1Y

o:section 4.3.2Firmware Upgrade:https://youtu.be/NOoLfDw0DiY

p:section 4.3.3Calibration:https://youtu.be/c9sn1wY2mjE

q:section 4.3.4Logo Update:https://youtu.be/vuVhBsohWts

r: RD6006 wifi connection Problem and solution:https://www.youtube.com/watch?v=7sTtc1kweJM

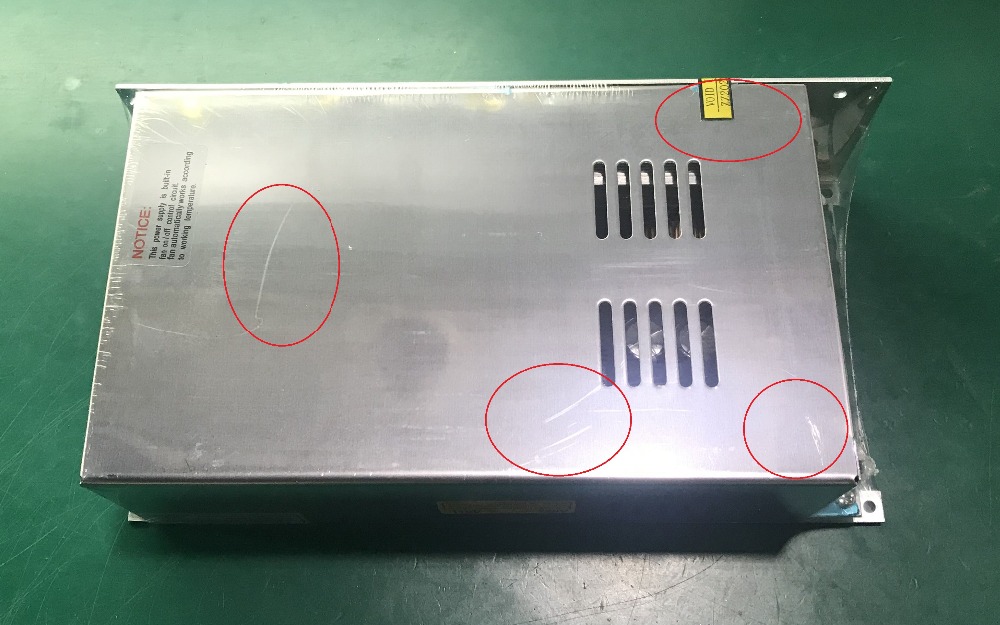

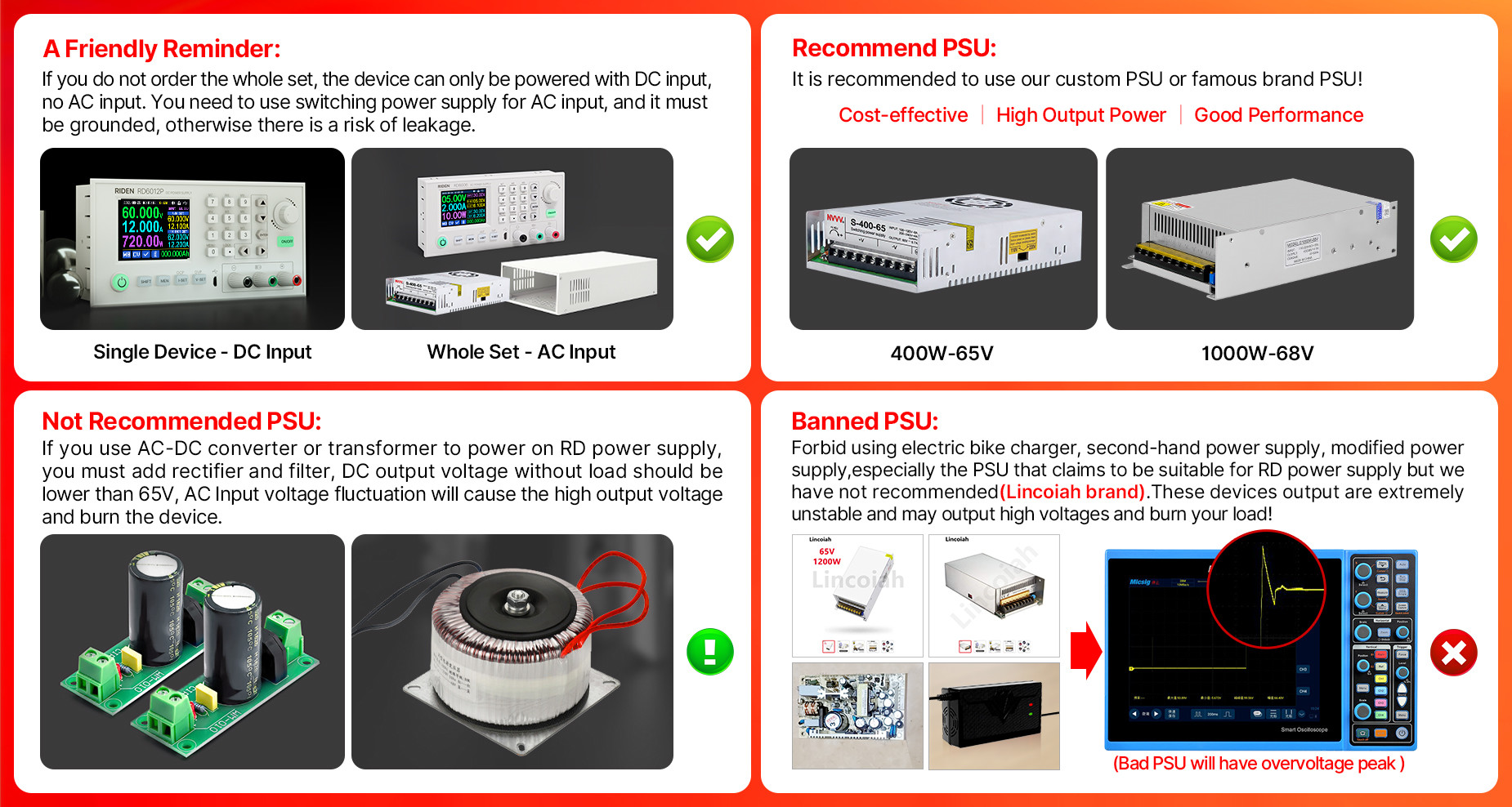

2,PSU Notification

If you order the PSU, after getting the PSU, please use multimeter to check if the real output voltage is stable and fits the rated voltage, to see if it is damaged on the way, if the output is abnormal, please contact us, do not connect it to RD power supply to avoid more loss

3,Assembly Notification

You can only connect the cables with a foundation in electronic and electrical engineering and it must be reliably grounded!

4,Correct Installation

5, Actual Test Video

https://www.youtube.com/watch?v=pz0T9rD4Ij0

PRODUCT QUESTIONS:

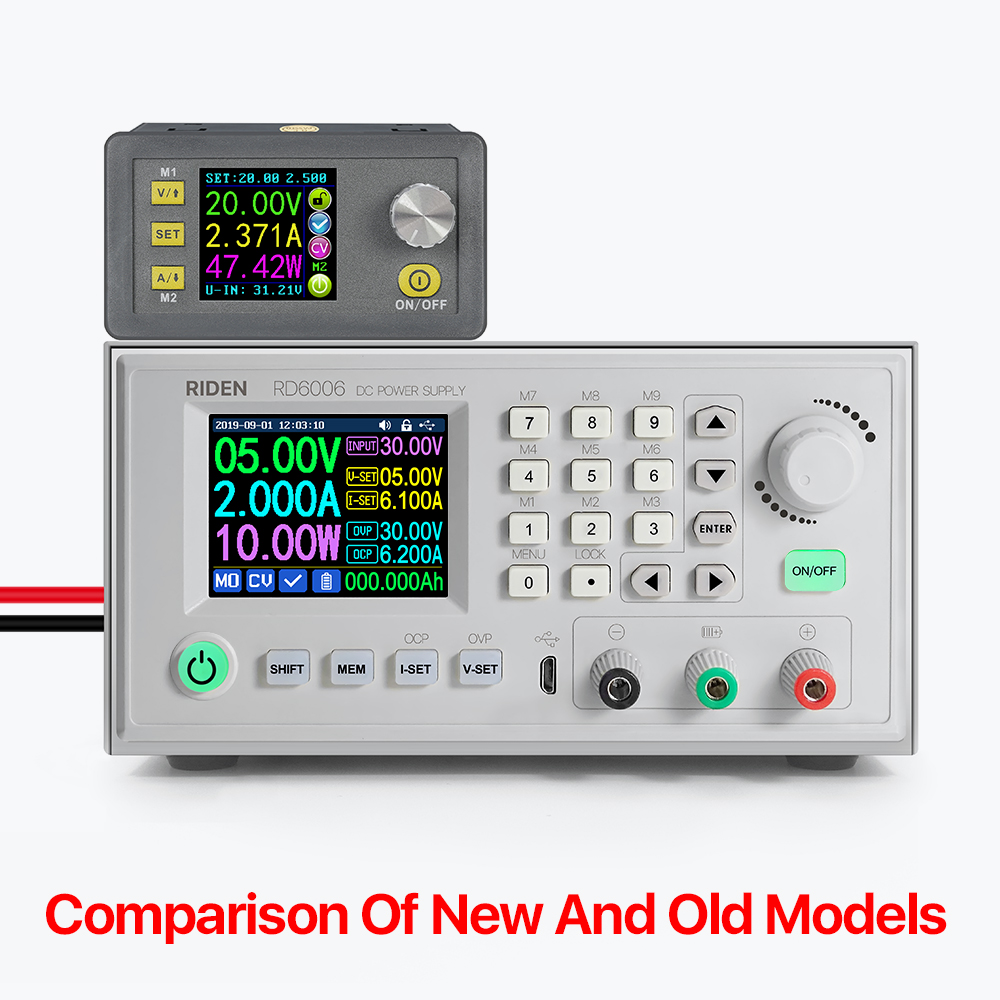

1. Q: What is the differences between RD6006 and RD6006-W?

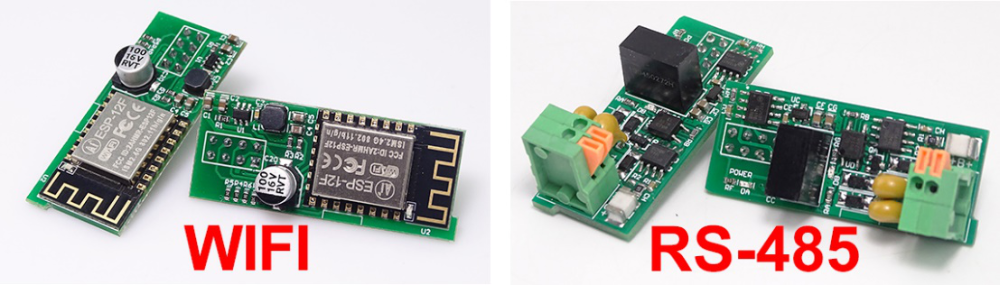

A: RD6006-W has WIFI board , RD6006 doesn't have. RD6006-W can use WIFI board to connect APP, also use USB micro cable to connect PC software . RD6006 doesn't have WIFI board, only support PC software by connecting with USB micro cable, no support APP.

2. Q: What can I get in this link?

A: the option title and pictures shows what you can get, please check and make the order.

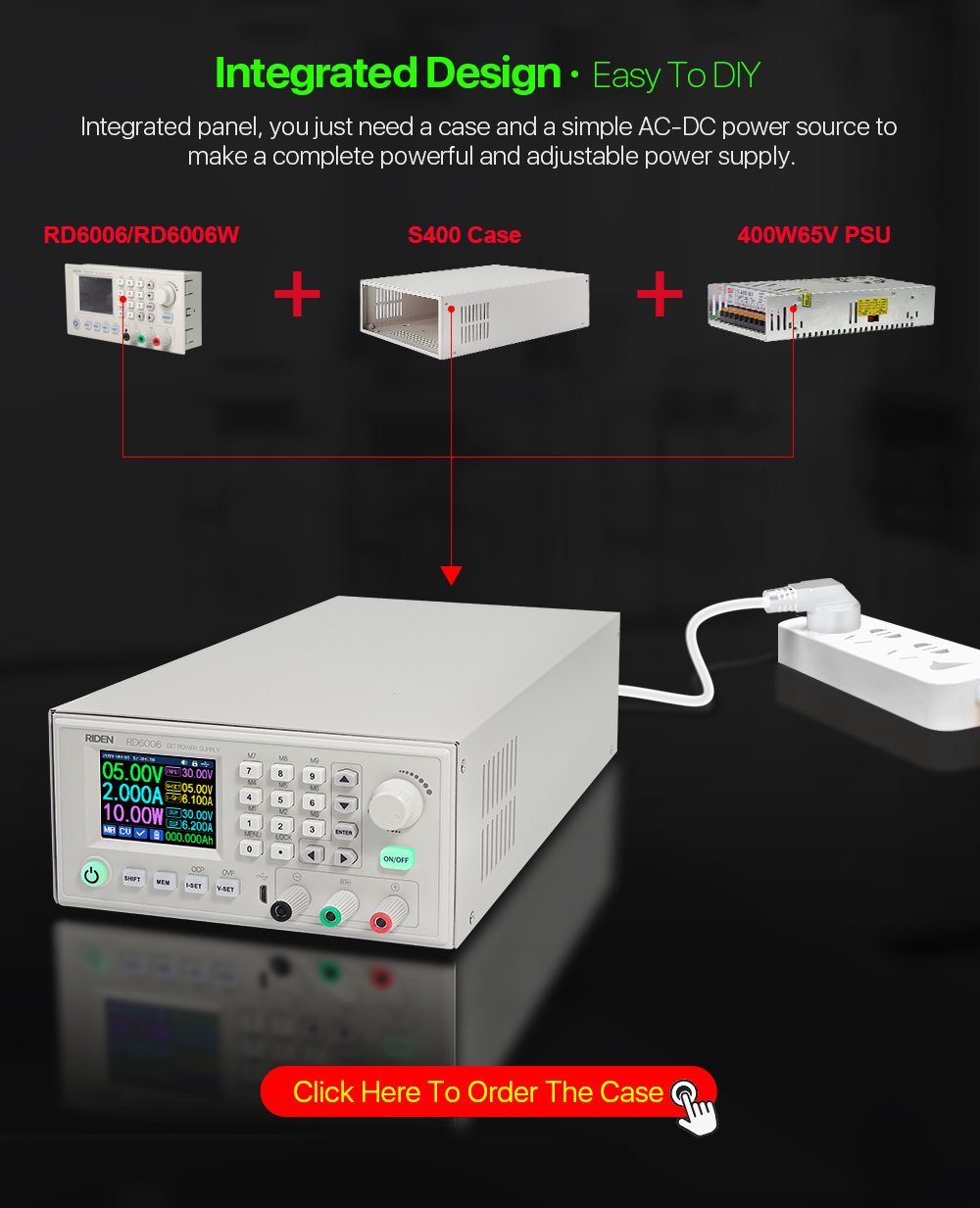

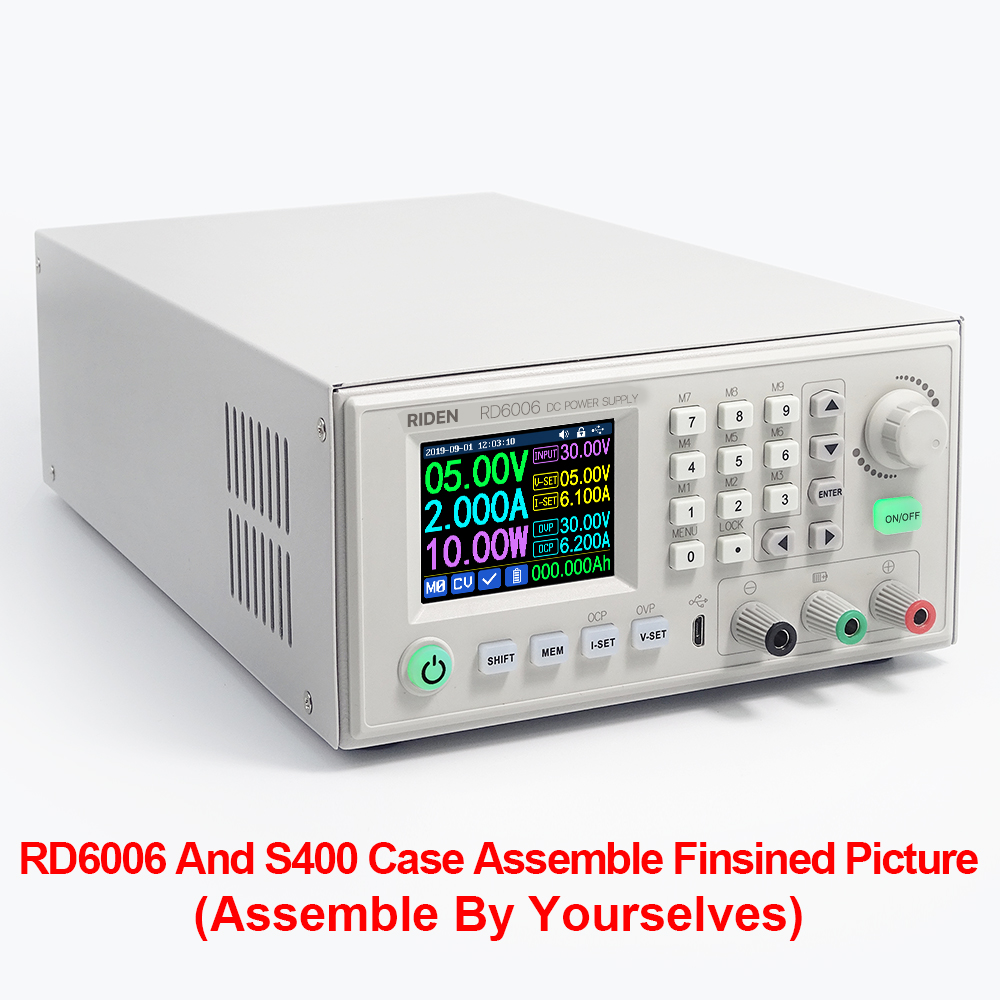

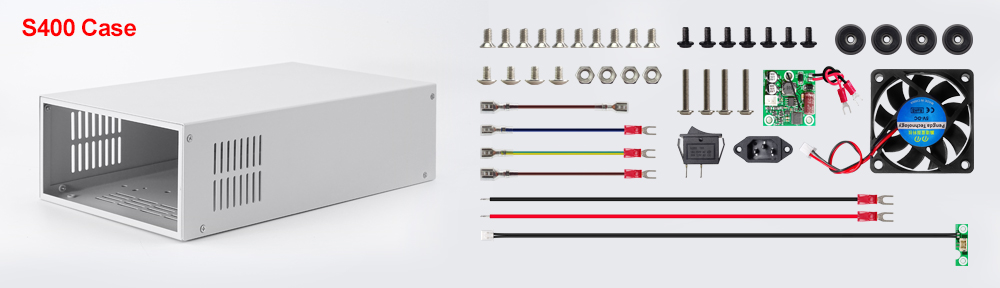

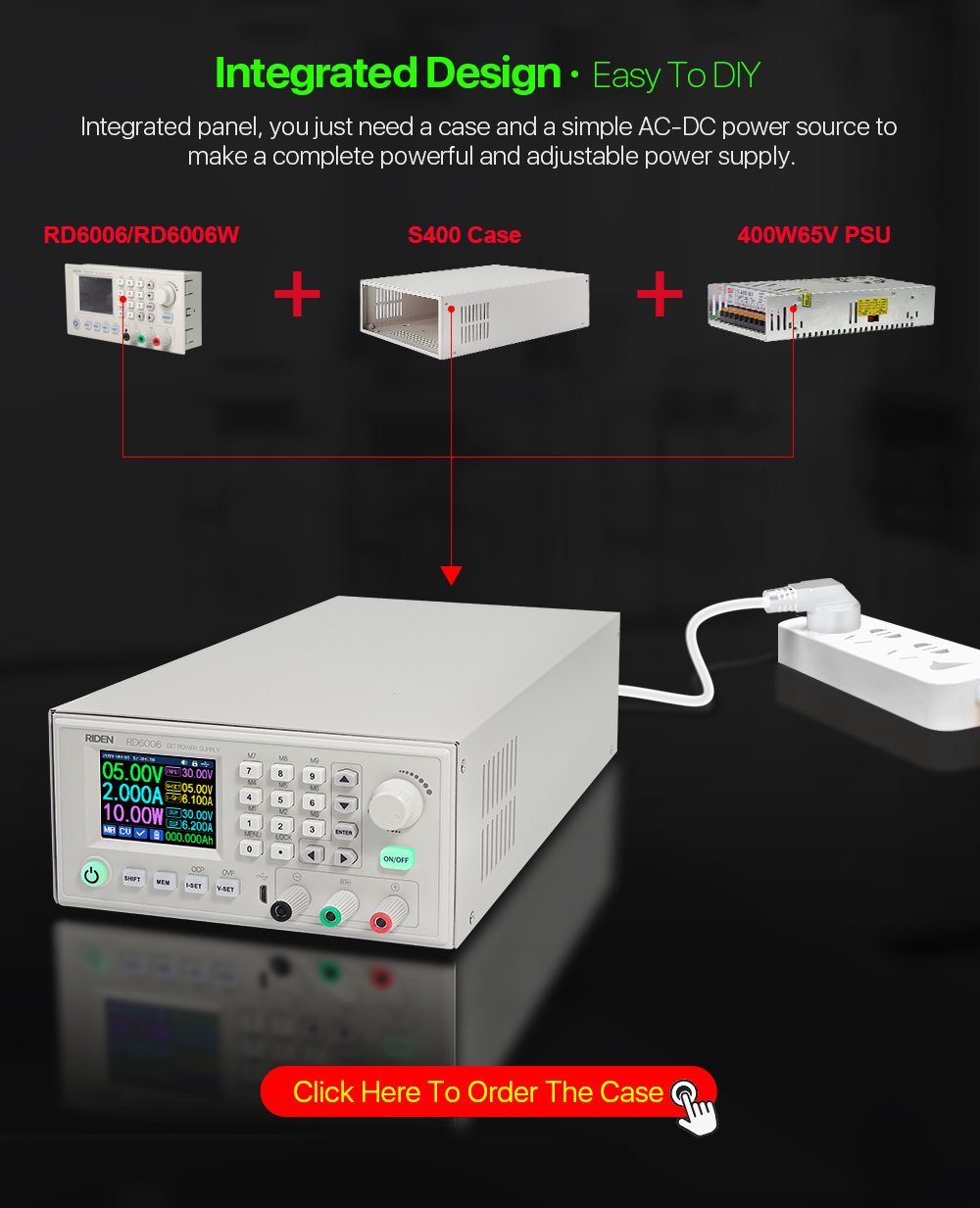

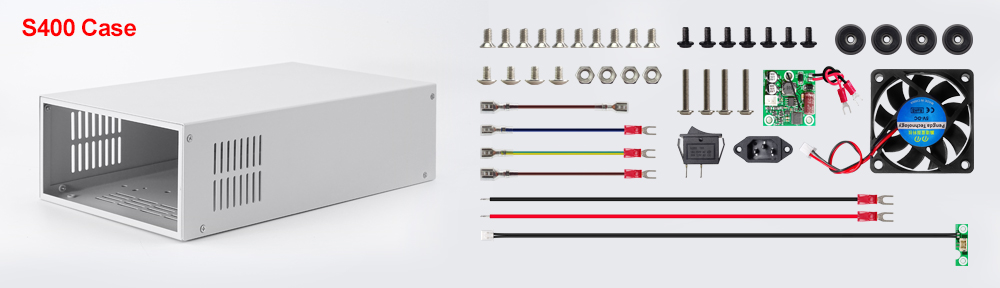

3. Q: What does S400 case contains?

A: For S400 case, it is just case, not containing any power supply, it contains the internal cables and screws, it is suitable for RD6006/RD6006W and AC-DC 400W switching power supply, you can buy them separately to assemble then together.

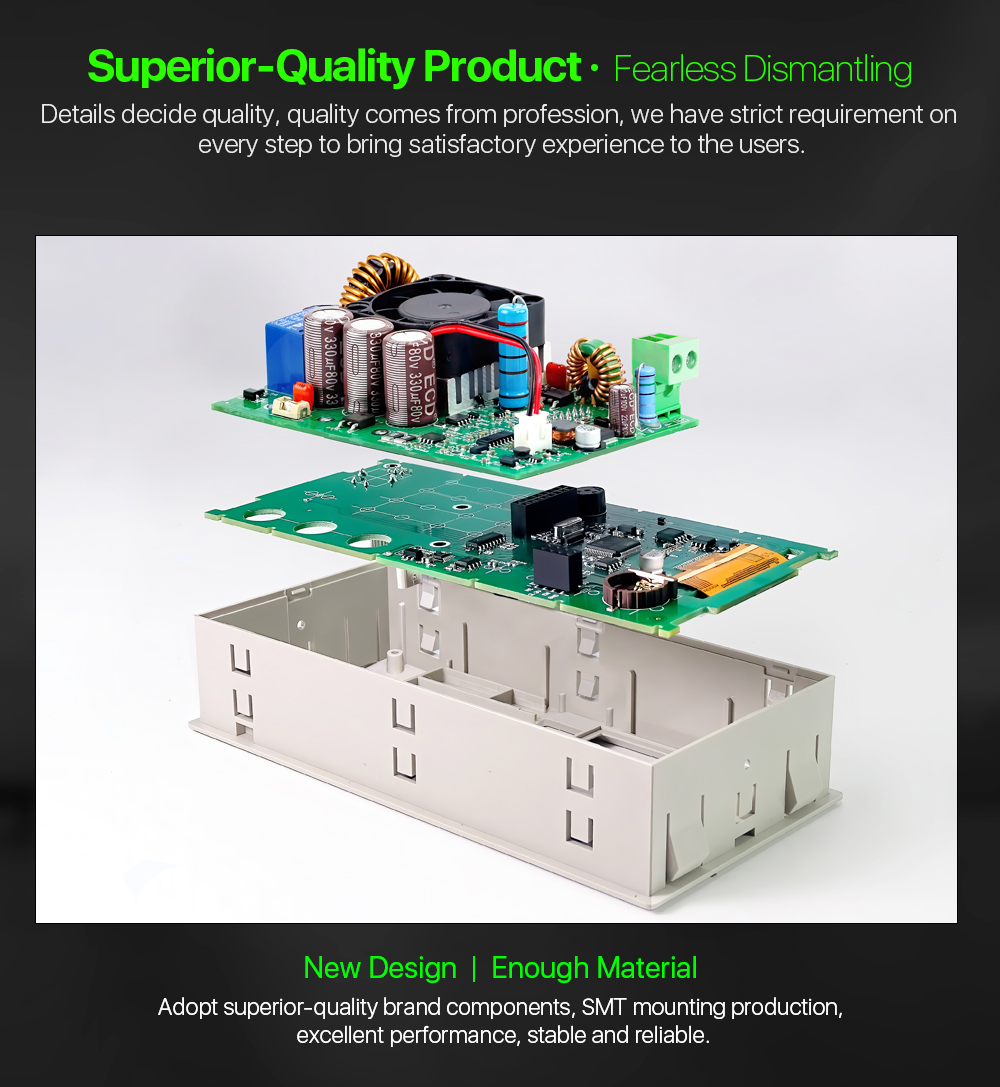

4. Q: Why the product I get is a bit different with the picture?

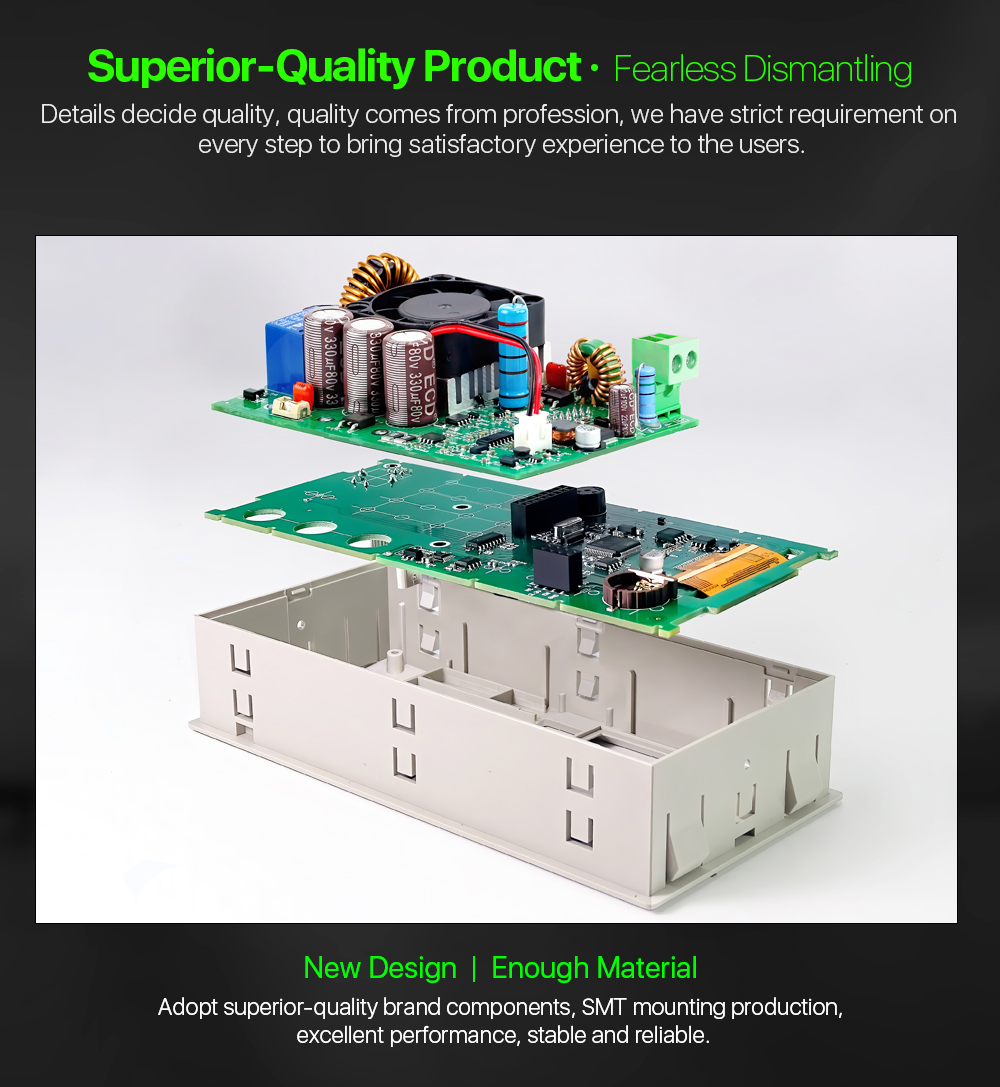

A: We keep updating the product hardware and software to make the device better, so the internal material details may be different, but it does not affect you to use the functions.

5. Q: why does the instruction not come with the product?

A: Because the products keep updating, we will add some function with the firmware and hardware update, so you can download the instruction online.

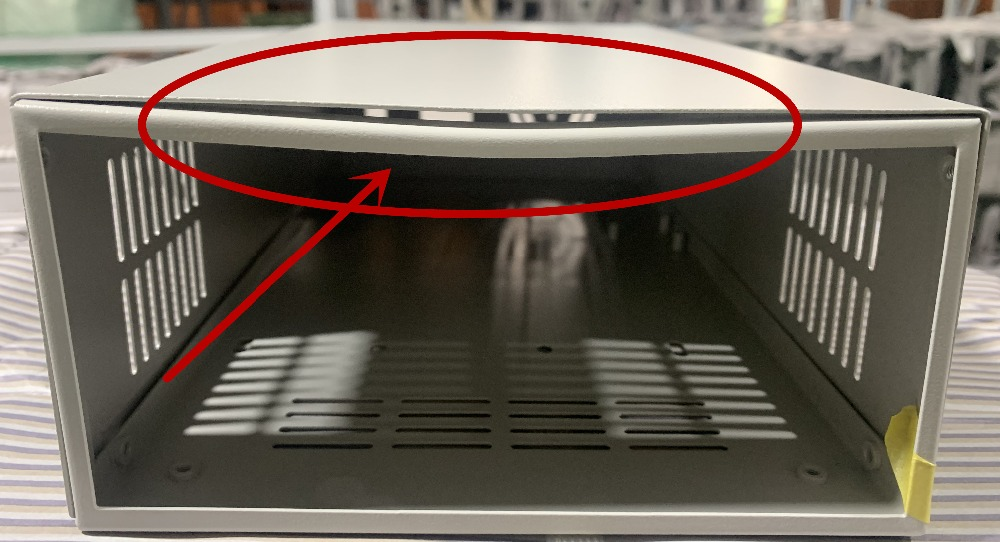

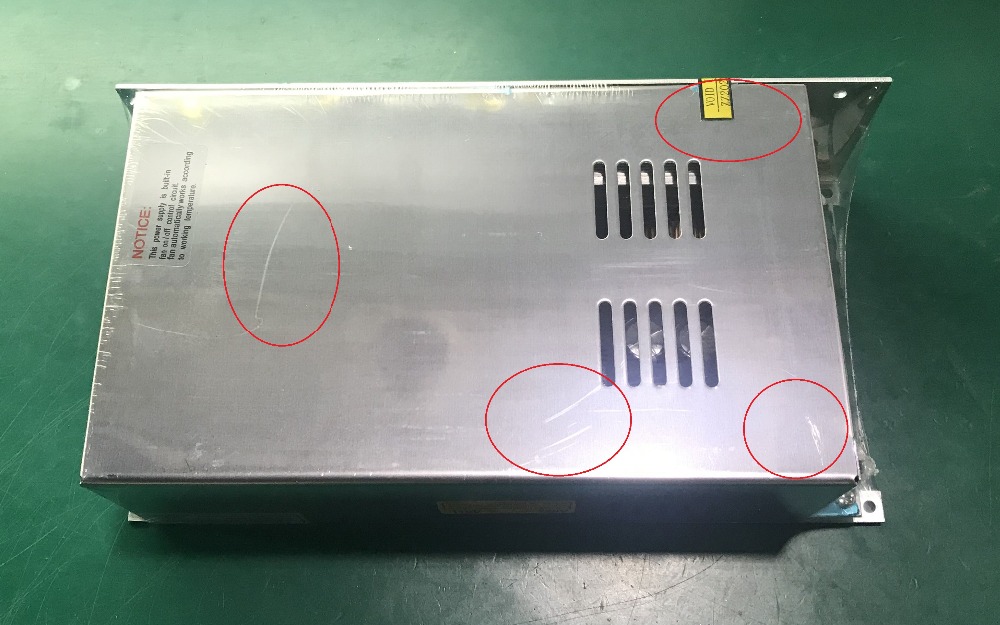

6. Q: the case I receive is a bit deformed?

A: For the case, during the shipping,maybe the case side will be a little deformed (just like picture ), you can use your hand to adjust, that's OK, if you mind this , please stop buying.

7. Q: the PSU I receive have some scratches?

A: There may be scratches on the surface but it doesn't affect the product performance, please do not be over picky, and if you do mind this, please do not buy this product

8. Q: the warranty label is broken, do I still get the warranty?

A: Due to express delivery, some power supply warranty labels may be damaged, which does not affect product warranty!

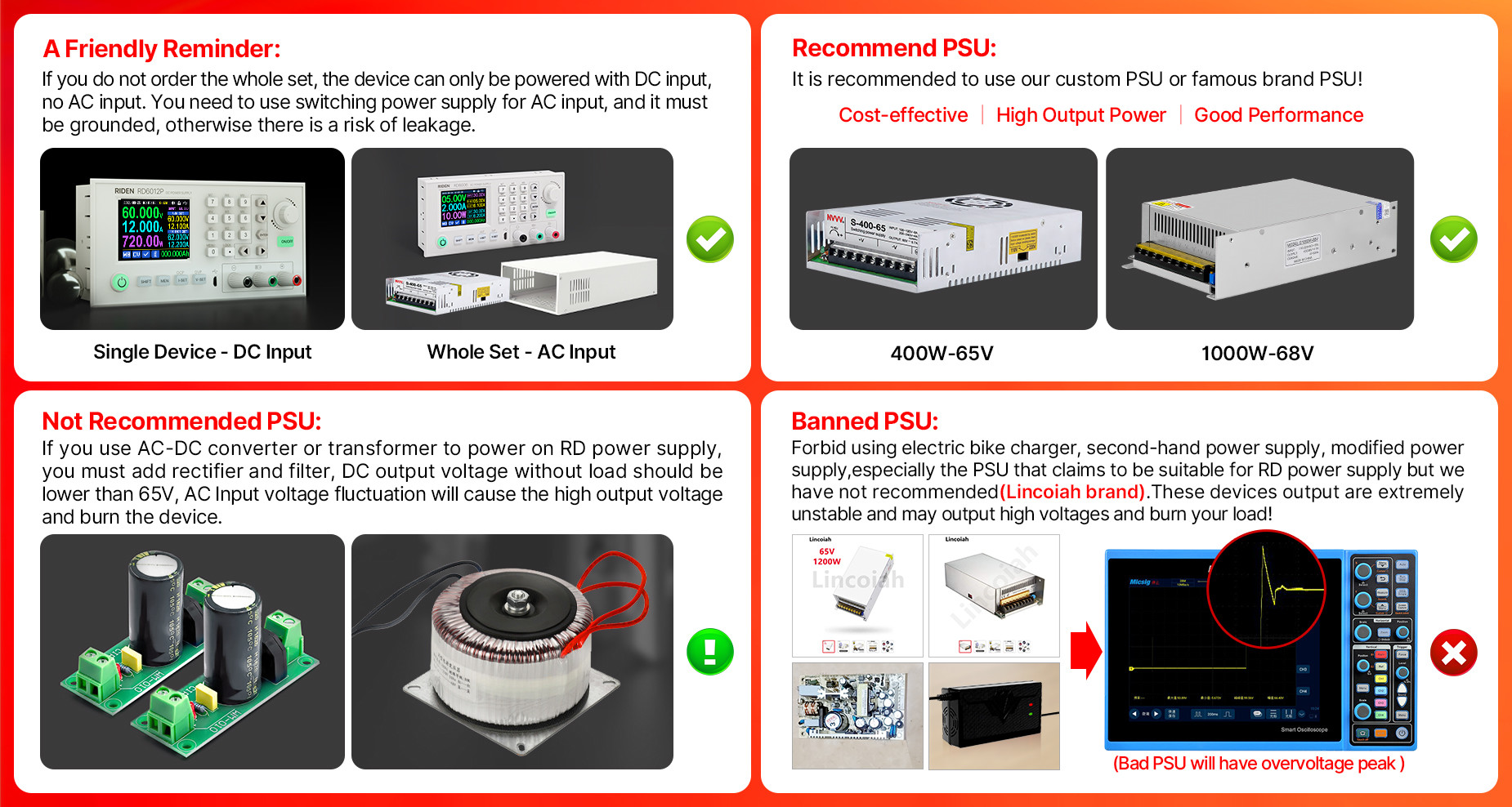

9.Q: How do I choose the PSU?

A:Friendly reminder, If you do not order the whole set, the device can only be powered with DC input, no AC input. You need to use switching power supply for AC input, and it must be grounded, otherwise there is a risk of leakage.

AA: Recommend PSU

It is recommended to use our custom PSU or famous brand PSU!

BB: Not recommended PSU

If you use AC-DC converter or transformer to power on RD power supply, you must add rectifier and filter, DC output voltage without load should be lower than 65V,power grid voltage fluctuation will cause the high output voltage and burn the device!

CC. Banned PSU

Forbid using electric bike charger, second-hand power supply, modified power supply, especially the PSU that claims to be suitable for RD power supply but we have not recommended ......These devices output are extremely unstable and may output high voltages and burn your load!

(bad PSU will have peak over-voltage)

11.Q: Can I use it to power on inductive load?

A: If you connect inductive load (such as motor), the max working current is 1/3 of range. don't exceed it.

12. Q:why there is a fuse in the box? Should I install it?

A:Itis a BACKUP fuse in the, if you burn the fusewith wrong operation, you can replace the fuse in the socketwith the backup fuse to fix it.

13. Q: can I remove the case of the PSU for better heat dissipation?

A: when install our PSU into the case, please follow our instruction to assemble, do not remove the shell of the PSU to use. After removing the shell of the switching power supply, the structural change of the heat dissipation system will lead to insufficient heat dissipation,and some components will be overheated and damaged, in this case we don't offer after sell service

SOFTWARE QUESTIONS:

1. Q: The APP crashes on my phone, what the problem is?

A: For APP and PC software, because there may be incompatibilities problems, please download first before buying , if you can download and install, you can make order, or else stop buying. If you don't test the PC software and APP function before buying and find that the products works fine except the PC software or APP, we refuse to refund.For PC software, it only support win 7 and above for now. For APP, it only support android 8.0 and above.

2. Why cannot I connect the RD6006W to my phone APP via WIFI?

A: Please check if the WIFI board is inserted properly, then check if the WIFI is 2.4G Hz and if you shut down the client isolation/ AP isolation and WMM function, and check if you turn on the location service and storage service when you install the APP. If there is still problem, contact us.

3.Why cannot I connect the RD6006W to PC via WIFI while I can connect to the Phone?

A:WiFi connection is a test function, due to poor compatibility of some computers, if you cannot connect PC software via WiFi, please ignore this function. Forthis function, we do not provide any guarantee and technical support, and we will decide whether to keep this function based on customer feedback.

| Model | RD6006 | RD6012 | RD6018 | RD6006P | RD6012P | RD6024 |

| Input voltage range | 6-70.00V | 7-70.00V | 7-70.00V | 6-70.00V |

| Output voltage range | 0-60.00V | 0-60.000V | 0-60.000V | 0-60.00V |

| Output current range | 0-6.000A | 0-12.00A | 0-18.00A | 0-6.0000A | 0-6.0000A/ 0-12.000A | 0-24.00A |

| Output power range | 0-360W | 0-720W | 0-1080W | 0-360W | 0-720W | 0-1440W |

| Output voltage setting measurement resolution | 0.01V | 0.001V | 0.01V |

| Output current setting measurement resolution | 0.001A | 0.01A | 0.0001A | 0.001A/ 0.0001A | 0.01A |

| Output voltage accuracy between setting and measurement | ±(0.3%+3 digits) | ±(0.5‰+4 digits) | ±(0.3%+3 digits) |

| Output current accuracy between setting and measurement | ±(0.5%+5 digits) | ±(1‰+6 digits) | ±(0.5%+5 digits) |

| Automatic cut off current value when charging | 10mA | 100mA | Set by yourself | Set by yourself | Set by yourself(higher than 100mA) |

| Output ripple typical | 100mV VPP | 250mV VPP@6A | 20mV VPP | 100mV@12A,150mV@24A VPP |

| Buck working mode | Voltage drop >1V and >10% | (input voltage÷1.1)-2 | (input voltage÷1.1)-1 |

| Weight(with package) | About 0.58kg | About 0.61kg | About 0.68kg | About 0.62kg | About 0.66kg | About 0.72kg |

| Product dimension | 167*81*65mm | 167*81*69mm | 167*81*65mm | 167*81*69mm |

①:Ripple measurement method: noise and ripple are measured at X1 range, AC coupling,

20MHz of bandwidth on your oscilloscope with a 0.1uF parallel capacitor at the output terminals

②for example: input voltage is 24V,the max output voltage is 19.8V.

Constant Voltage and Constant Current

DC Power Supply Instruction

Model: RD6006/RD6006-W

1.1Core Function

·keypad + encoder potentiometer combination adjustment

·2.4 inch HD color screen

·Battery charging special interface

·Data quick storage & recall

·New PC software

·Wi-Fi connection, Phone APP control

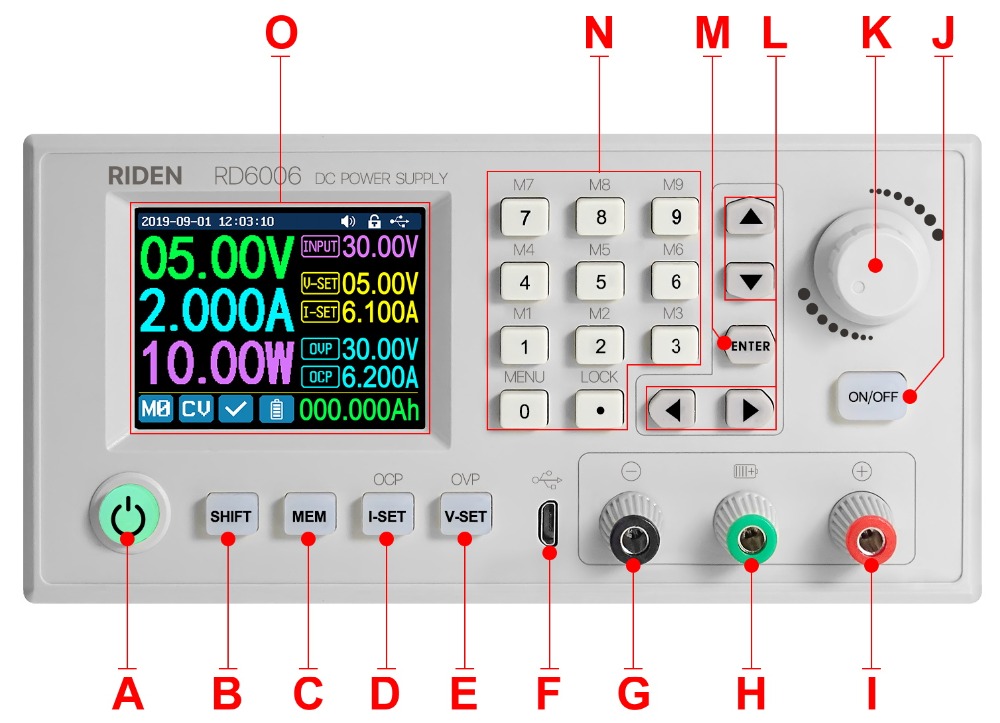

1.2Panel Description

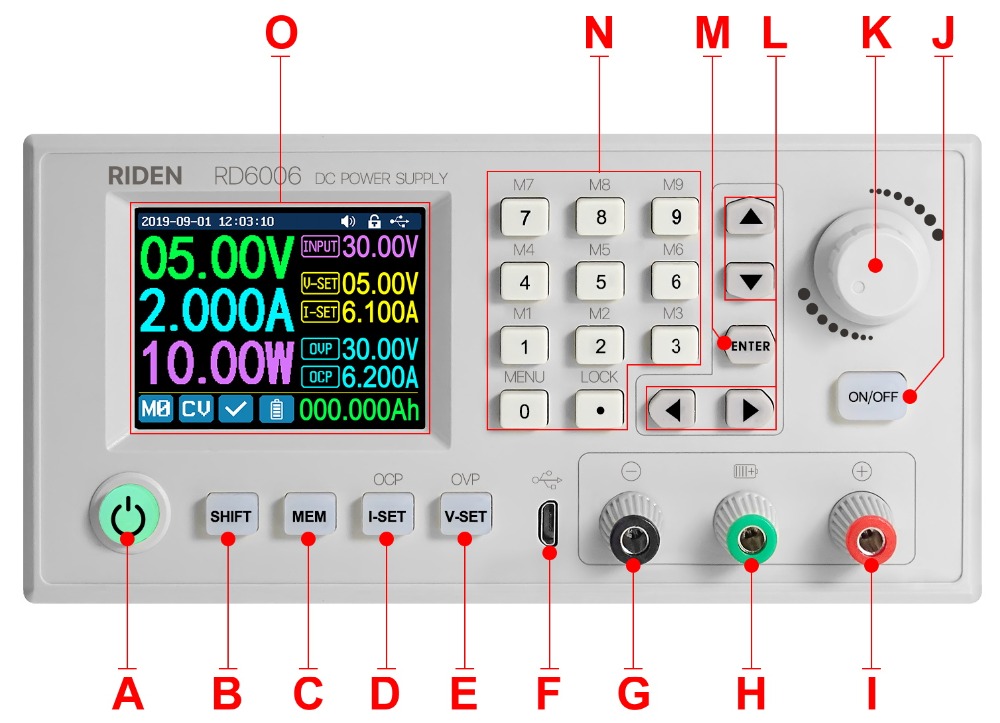

1.2.1Front panel

| A: Power button | B: Second function button |

| C: Quick storage button | D: Current/Over current protection value setting |

| E: Voltage/Over voltage protection value setting | F: Micro USB interface |

| G: Power supply output negative electrode Battery charging negative electrode | H: Battery charging positive electrode |

| I: Power supply output positive electrode | J: Output switch |

| K: encoder potentiometer/Cancel button | L: Direction button |

| M: Confirm button | N: keypad |

| O: Screen | |

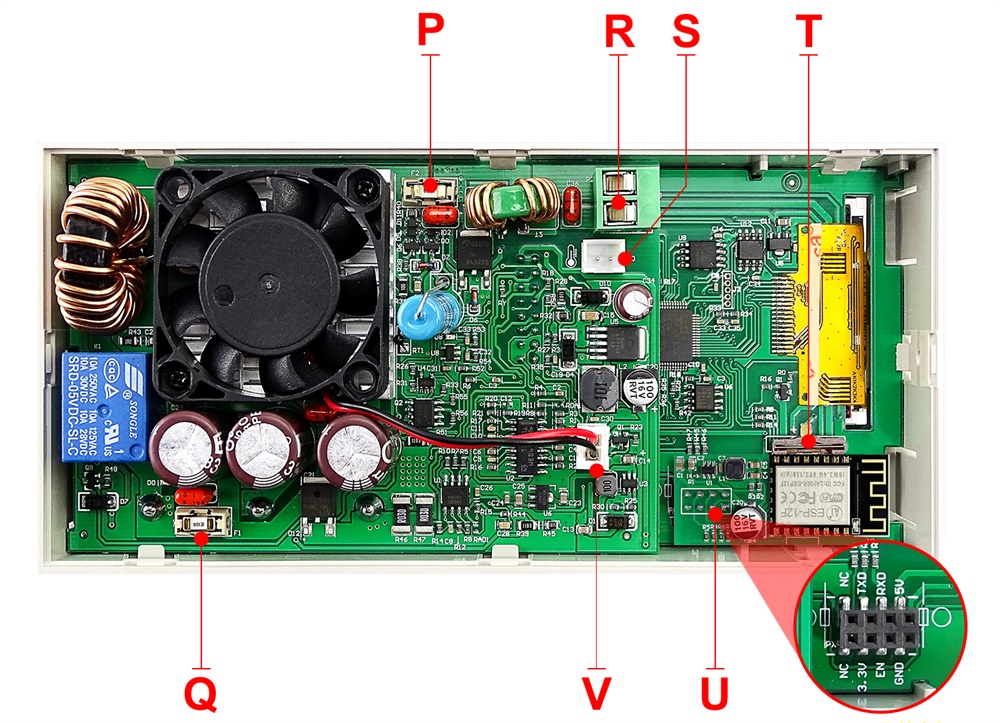

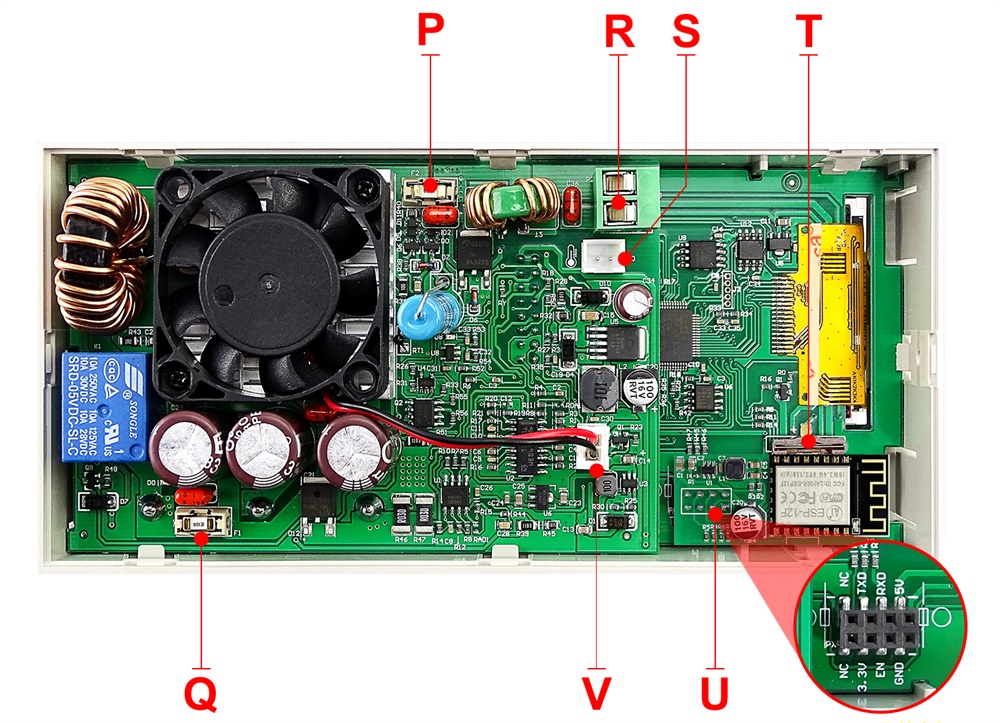

1.2.2Back panel

| P: Input fuse | Q: Output fuse |

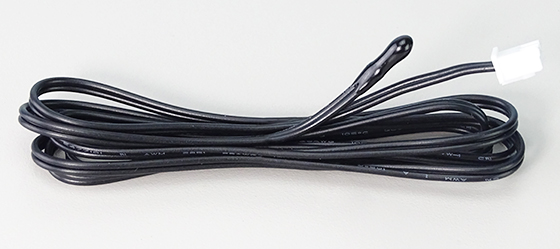

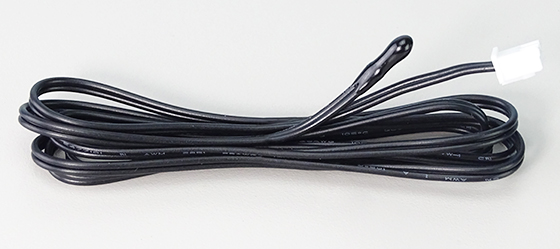

| R: Power source input interface | S: External temperature sensor interface |

| T: CR1220 battery socket | U: Communication module interface |

| V: Fan interface | |

NOTE:

Power source input interface must be connected to 6-70V constant DC power source. The external sensor cable (as shown on right) must be connected to the external temperature sensor interface. The fan interface cannot be connected to other fans. When the output current is higher than 4A or the system temperature higher than 45℃, the fan start to work, when the temperature is less than 40℃ and output current lower than 3.9A, the fan will stop working. When the system temperature is higher than 80℃, the output will be shut down because of OTP. CR1220 is the clock battery(Please prepare by yourself), communication interface is a special interface, please don’t connect to other modules or cables.

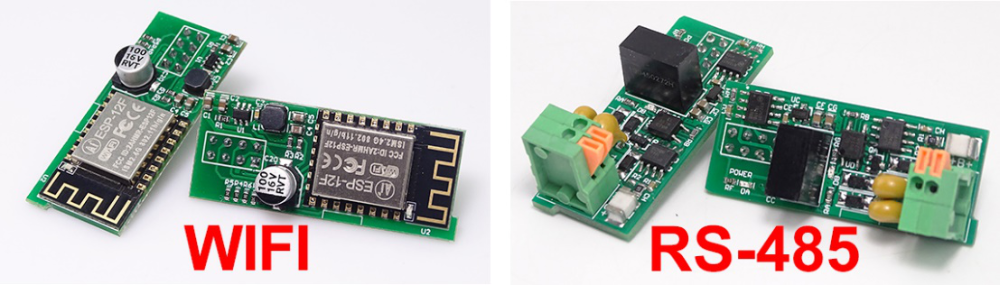

You can see the Wi-Fi module(RD6006-W contains) and RS-485 module in the picture below. If you need RS-485 for industrial batch test and it is not on sale now, if you want to use that, please contact us.

1.3Operation Introduction

After power-on, the boot image is displayed first, then enter the main page.

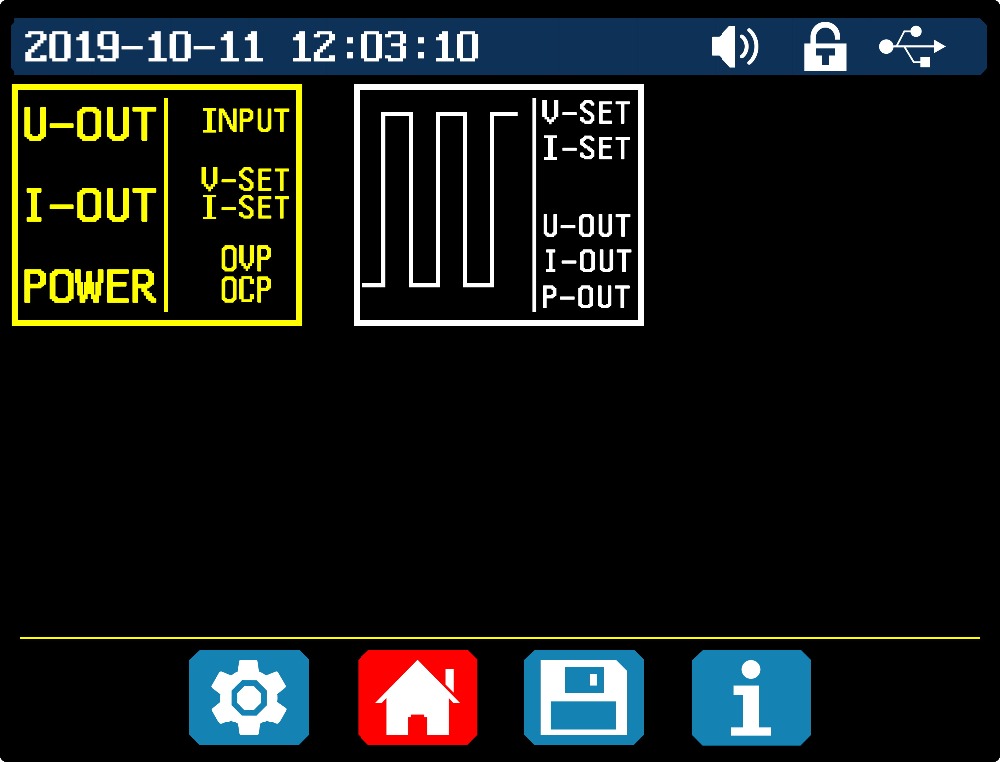

1.3.1MainPage

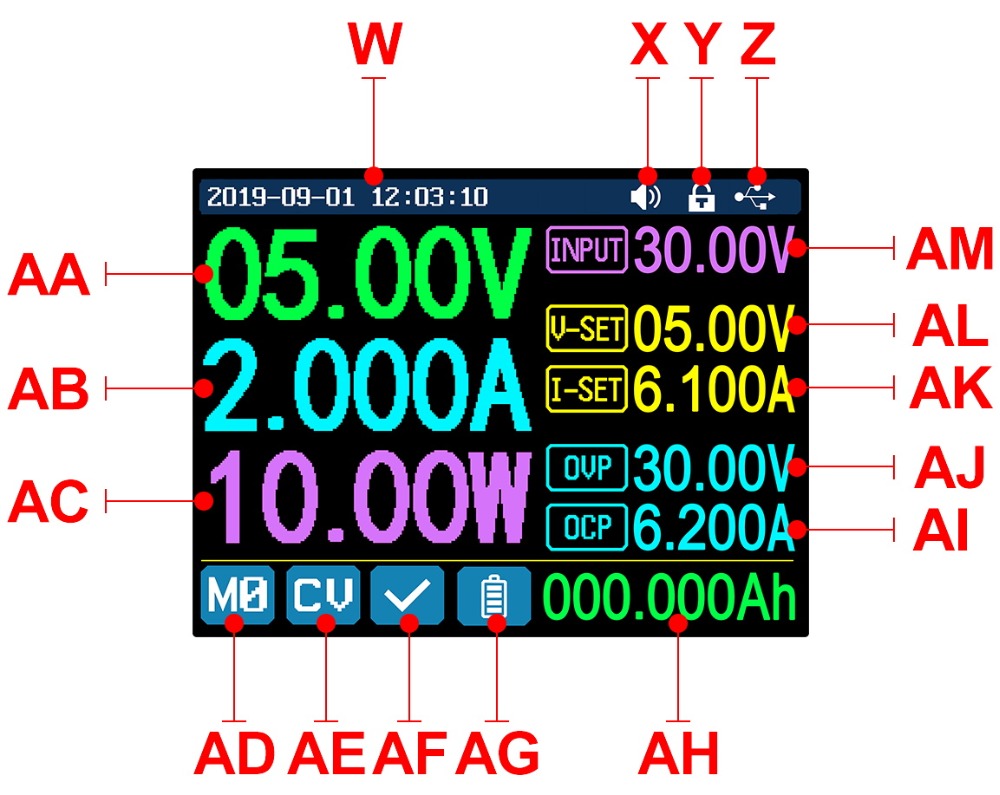

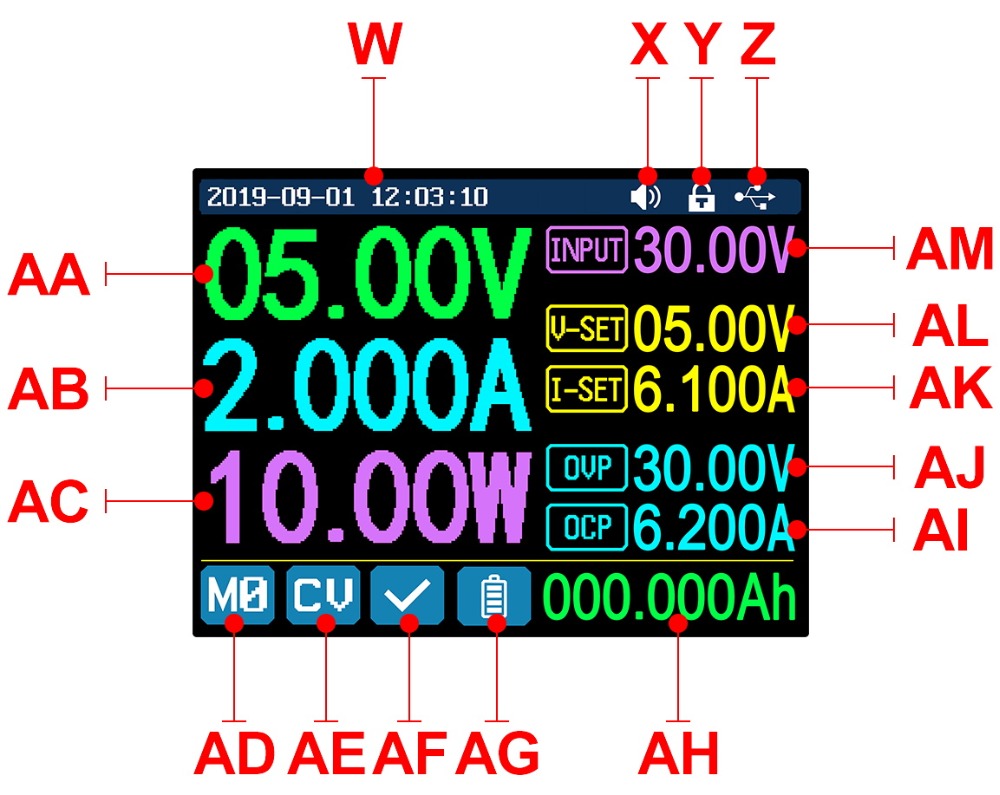

| W: Time | AF: Protection status indication |

| X: Button tune | AG: Battery charging indication |

| Y: Button lock status | AH: Battery related information display area |

| Z: Communication interface | AM: Input voltage |

| AA: Actual output voltage | AL: Output voltage preset value |

| AB: Actual output current | AK: Output current preset value |

| AC: Output power | AJ: Over voltage protection value |

| AD: Current data group | AI: Over current protection value |

| AE: Constant voltage Constant current status | |

1.3.2Operation Instruction

In the menu operation, the icon in red or cursor is the currently selected menu, the icon in blue is the unselected menu, pressENTERto confirm, press the encoder potentiometer to cancel or return, press the direction key to move the cursor or switch menu, rotate the encoder potentiometer to change the setting, the settings will be automatically saved when returning from the menu page. Press and hold the 0 button and power on to restore the factory settings, press and hold the 1 button and power on to restore the factory calibration value, press and hold ENTER and power on to enter the boot mode.

1.3.2.1Battery ChargingFunctionIntroduction

After power-on, at battery related information display area, external temperature, capacity and energy will loop display. When there is output current: capacity, energy automatically Accumulated, and automatically cleared after shutdown.

The green terminal is connected to the positive pole of the battery, and the black terminal is connected to the negative pole of the battery. After the battery is correctly connected, the battery charging indicator turns red and the battery is connected. Press ON/OFF to start charging, the battery charging indicator turns green. When the actual output current is lower than 10mA, the output will be shut down automatically. Battery with protection board may not be charged. The charging voltage and current should be set on your own.

It is strongly recommended to use the original charger to charge the battery. There is a risk of fire and explosion during the charging process. Non-professionals should not operate.

1.3.2.2Main Page Output Voltage and Output Current Setting

Press “I-SET”button to set the output current value, you can use encoder potentiometer to adjust the output value directly, press the direction button to move the cursor. Of course you can use keypad to set the value, and press “ENTER” to confirm. If you set the wrong value, you can press encoder potentiometer to cancel.

Press “V-SET”button to set the output voltage value, the operation method is similar to output current setting.

Press“SHIFT”+ “I-SET”button or“SHIFT”+ “V-SET”button to set the over current protection/ over voltage protection value. The operation method is similar to output current setting.

M0 is the default data group when RD6006 is powered on, manually modify the settings and automatically remember to M0 after confirmation.

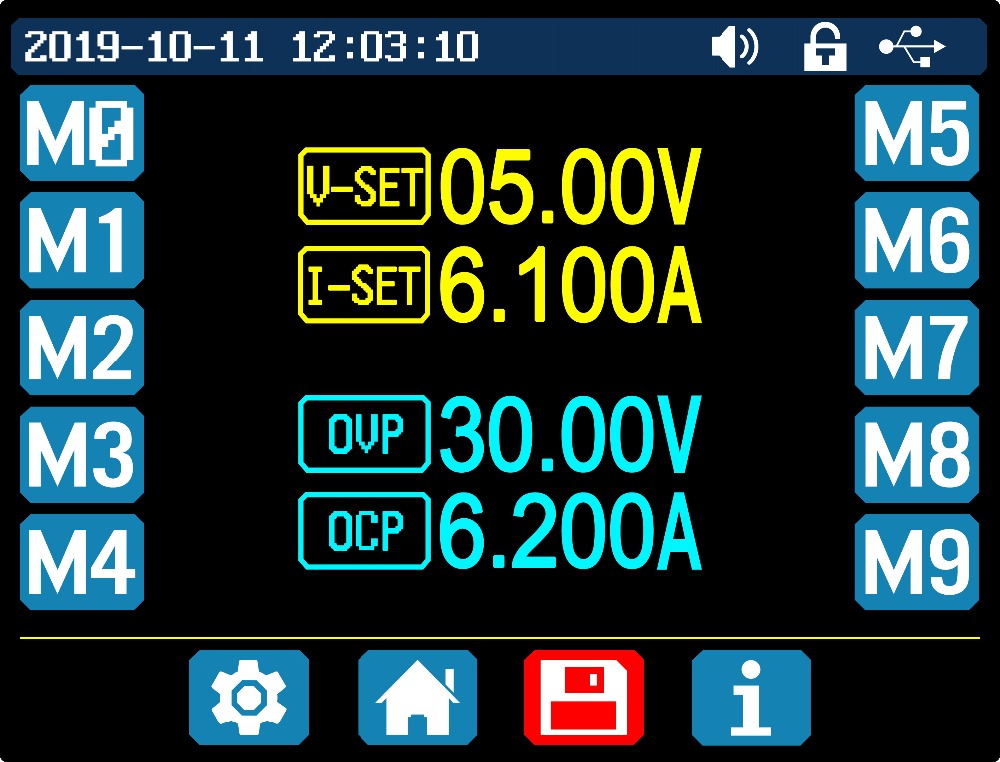

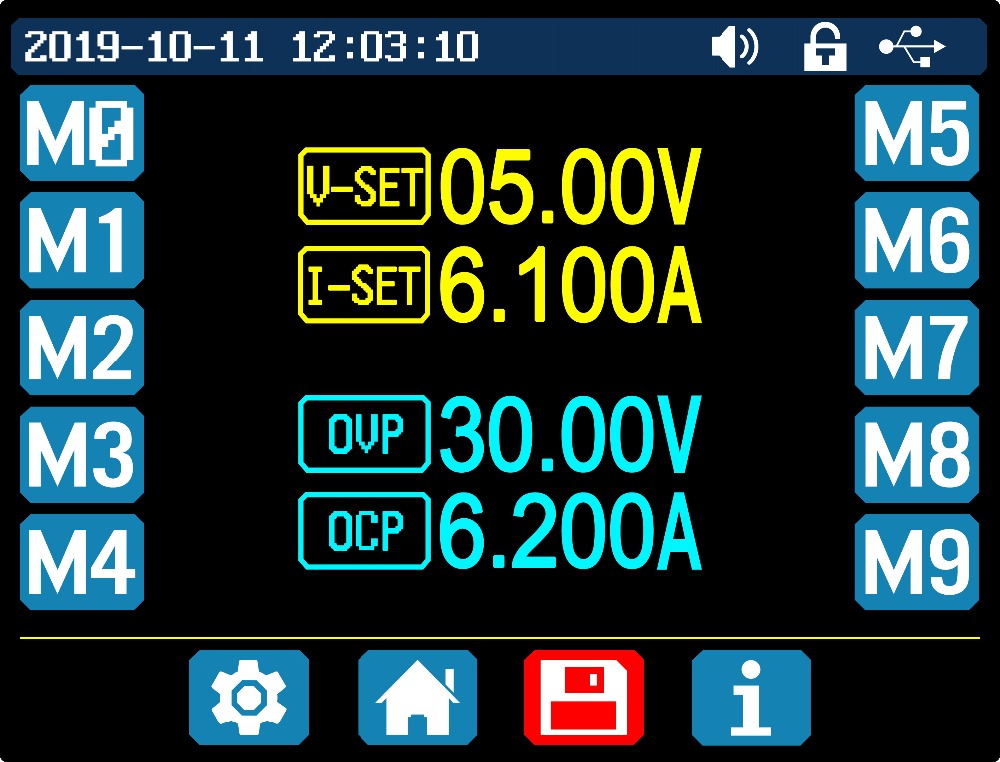

1.3.2.3 Data Group Quick Storage and Call out

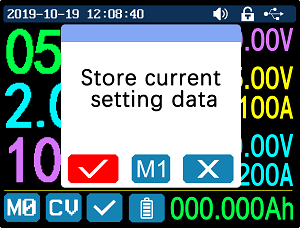

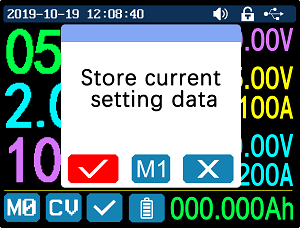

Press“MEM”+keypad button 1-9, you can store the output voltage value, output current value, over voltage protection value, over current protection value into the corresponding data group(as shown above), then press“ENTER”to confirm, or press the encoder potentiometer to cancel.

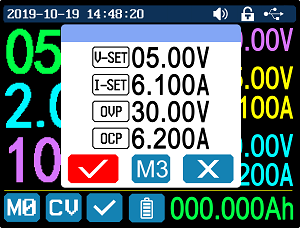

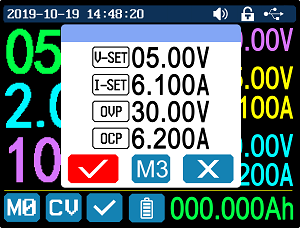

Press“SHIFT”+keypad button 1-9 to quick call out the saved data(as shown above). Press“ENTER”to confirm, or press the encoder potentiometer to cancel.

1.3.2.4 Keypad lock and unlock

Press“SHIFT”+”LOCK”to lock or unlock the keyboard. And the keypad will be automatically locked when communication starts, there will be

displayed on the top(can not unlock manually ), and the keypad will be automatically unlocked when the connection disconnected manually, there will be

displayed, the keypad will be automatically unlocked when the connection disconnected abnormally, and the power off button can be used when the keypad is locked.

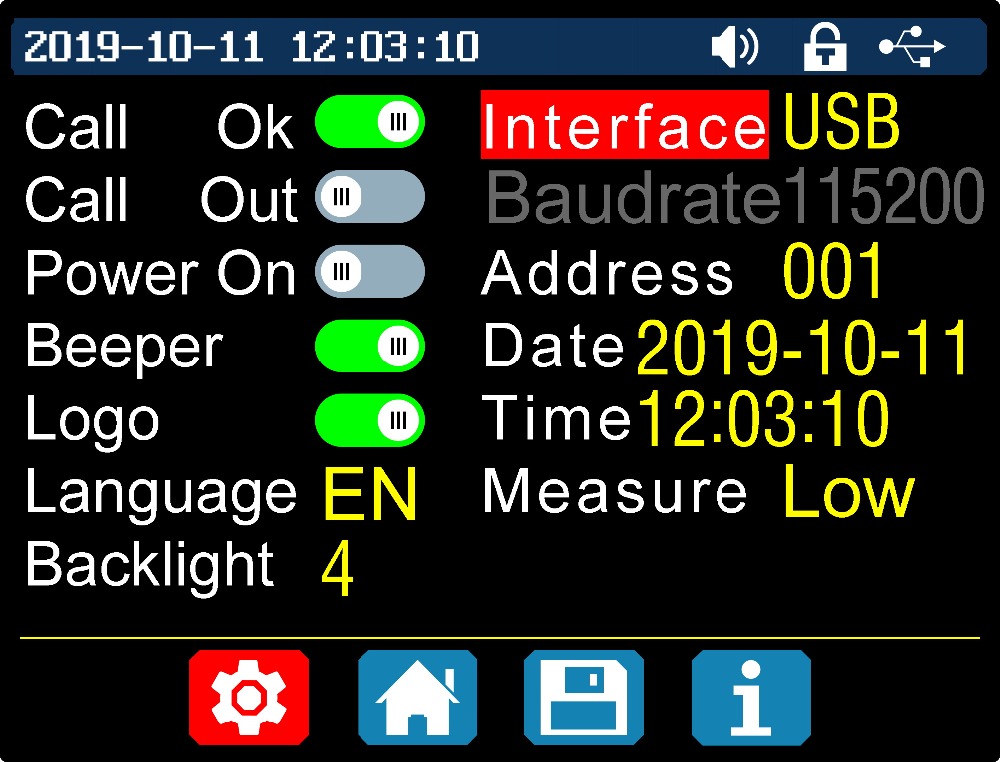

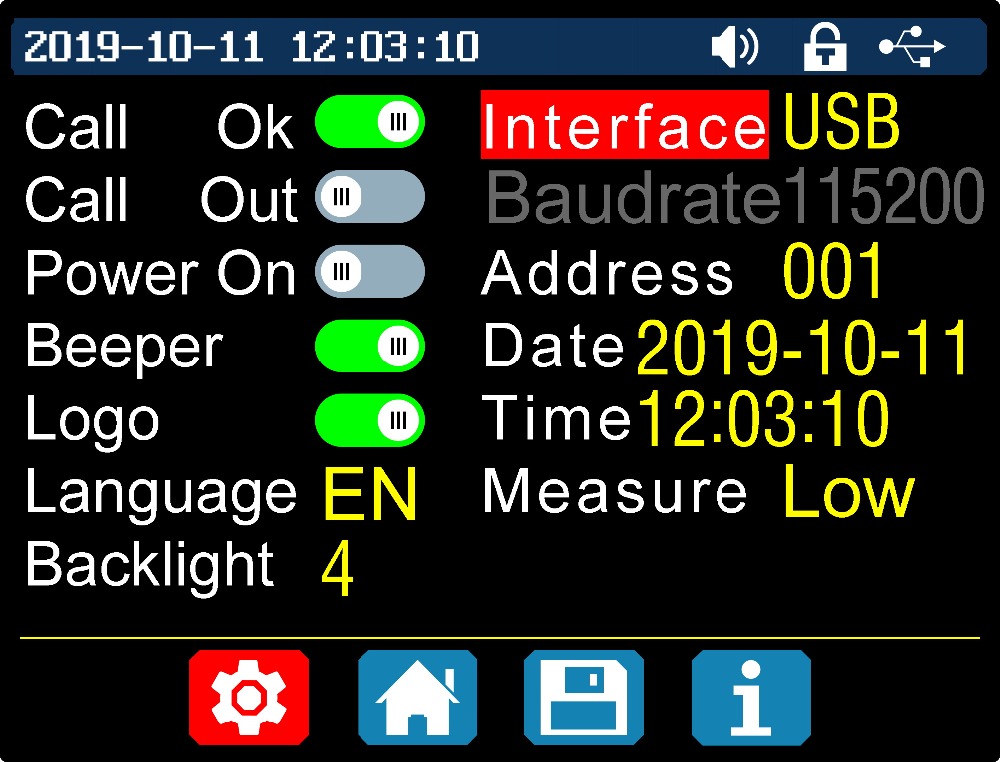

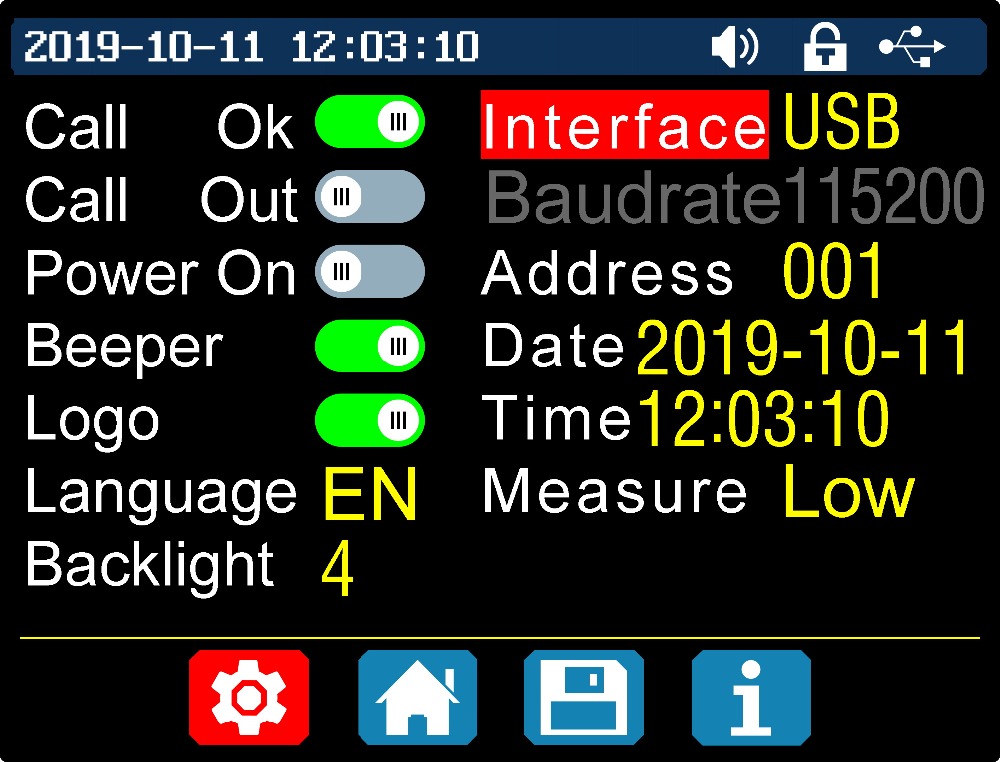

1.3.2.5 System Setting

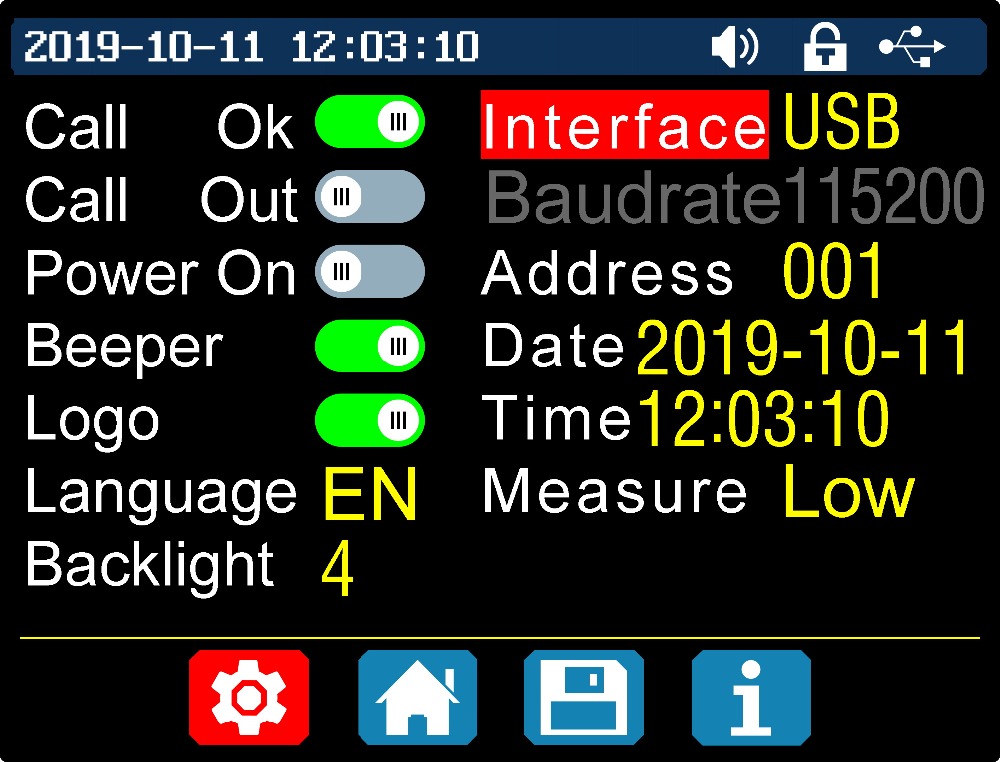

Press“SHIFT”+”MENU”to enter the system setting menu as shown on the right, press“ENTER”to enter the menu, press direction button to select option, the option in red is the option be chosen, rotate the encoder potentiometer to change setting.

Turn on the “Call OK”, a confirmation window will pop up when you quick call out a data group. If you turn it off, the setting values will be modified directly when you call out a data group.

Turn on the“Call out”, the output will be turn on automatically when you call out a data group. If you turn it off, the output will keep the previous status.

Turn on the“Power On”,it will turn on the output automatically when start. If you turn it off, the output will keep OFF status when started.

Turn on the“Beeper”,you will hear button tune when press the button, and there will be

on the top. If you turn it off, there will not be button tune when press the button, and there will be

on the top.

Turn on the“Logo”, it will display Logo first and then enter the main page when boot RD6006. If you turn it off, you will enter the main page directly.

The system language supports Simplified Chinese and English for the time being; the screen brightness can be set from level 0 to level 5; The communication interface can be set to USB, Wi-Fi or TTL,USBinterface is the Micro-USB interface on the front panel interface, you can see the

on the top when communication starts.Wi-Fiinterface is the Wi-Fi module connected to the communication interface, you can see the

on the top when communication starts (connect mobile phone by Wi-Fi, but you need to choose Wi-Fi interface first, Wi-Fi module can not be installed or removed when RD6006 is powered on),TTLis not available for the time being; When the interface is changed, you need to reboot RD6006 to apply the modification. The baud rate can be set 9600/19200/38400/57600/115200 under USB mode; The Baud rate under Wi-Fi is fixed at 115200. Device address can be set from 001-255. You can set the date and time by rotating the encoder potentiometer, the setting will be saved immediately after modification. Please do not set a wrong time, it may cause the date to not be automatically accumulated. Press the encoder potentiometer to return, and the set value will be saved automatically.Measureis the refresh rate of read back voltage and current in the main page, you can set it to low, middle and high. Press encoder potentiometer to return and it will be automatically saved.

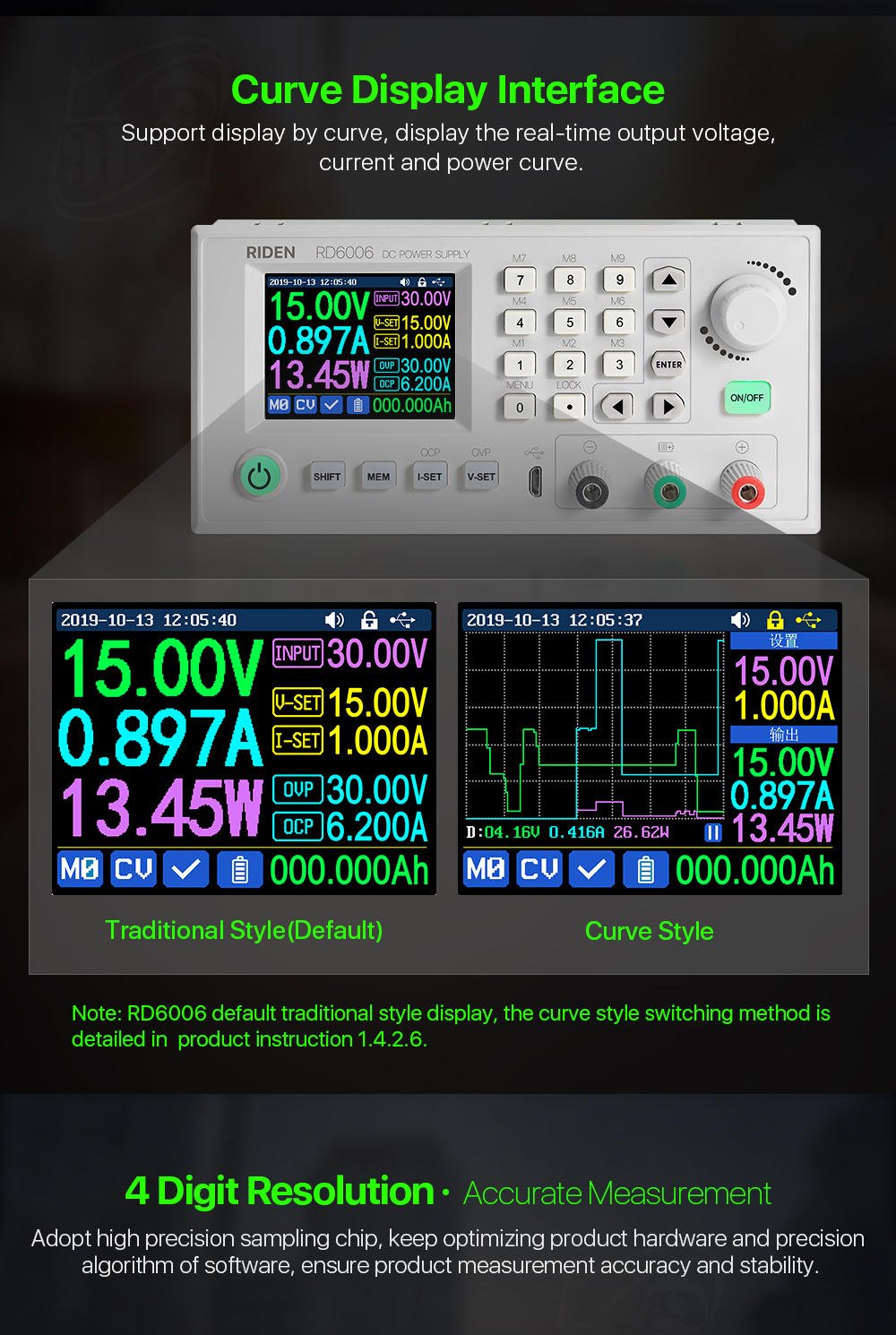

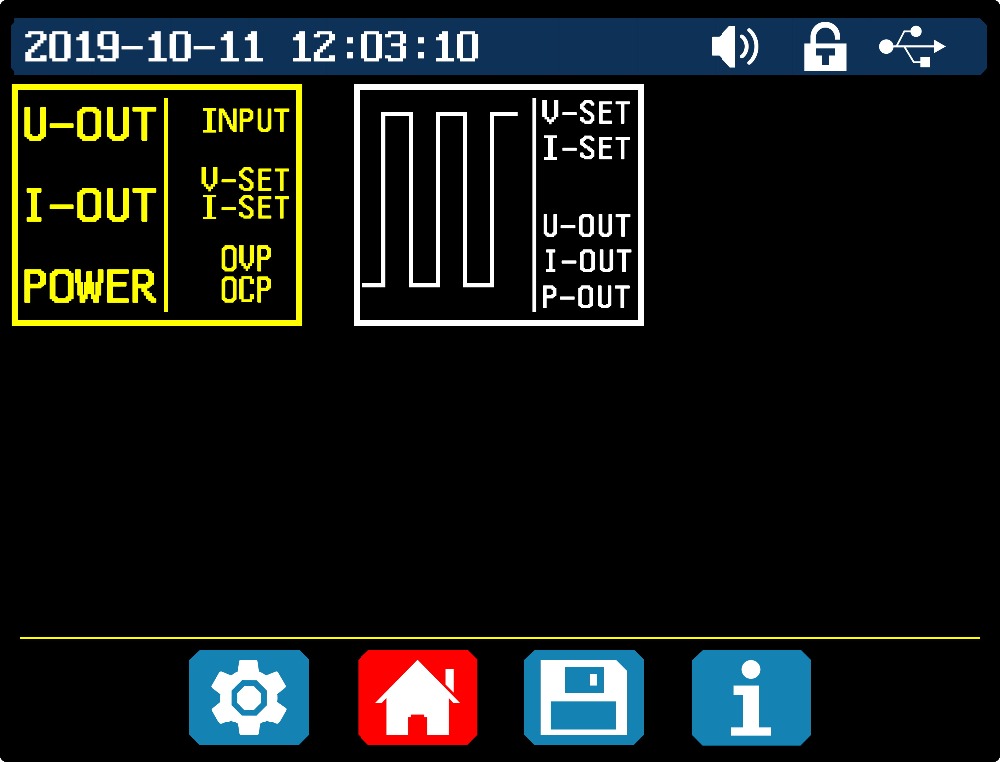

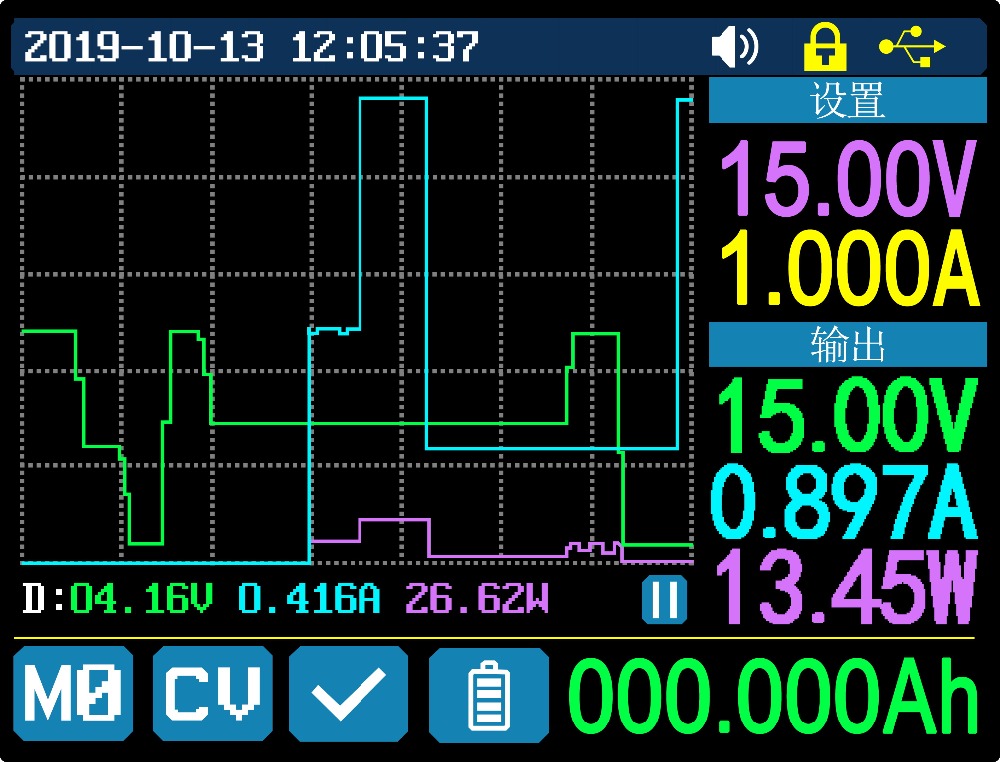

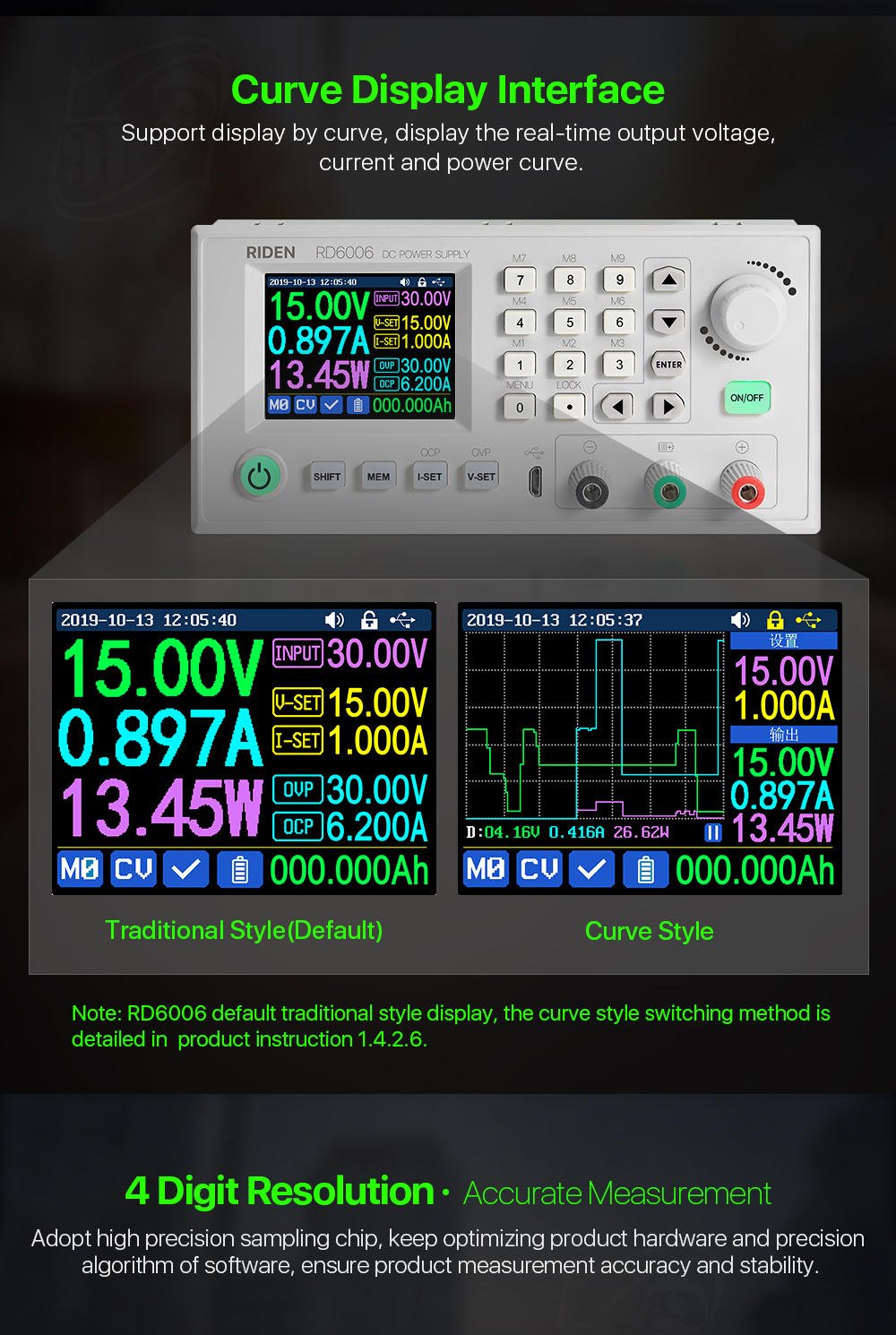

1.3.2.6 Main Page Style Setting

You can press SHIFT + MENU to enter the system setting menu, and then press the right button to enter the main page style setting menu as shown above. Press ENTER and then use direction button to set classic style or curve style. The pattern in red is the style be chosen. The classic style is the system default style, and the large font shows the voltage, current and power. The curve style is as shown above, the color of the three curves corresponds to the output voltage, current and power. D is the scale of the ordinate, Press“ENTER”to start or pause the curve, and the rotate encoder potentiometer to scale the ordinate of the curve.

1.3.2.7 Storage Data Setting

You can press SHIFT + MENU to enter the system setting menu, and then press the right button twice to enter the data storage setting menu as shown below, press ENTER to enter the setting menu, the icon in red is the chosen data group, press the direction button to select data group number. Press “I-SET”button to set the storage output current value, then rotate the encoder potentiometer the adjust the output value, press the direction button to move the cursor. You can also set the value with keypad, press ENTER to confirm. If you set the wrong value, you can press the encoder potentiometer to cancel. Press “V-SET”button to set the storage output voltage value, the operation method is similar to storage output current setting.

Press“SHIFT”+ “I-SET”button or“SHIFT”+ “V-SET”button to set the storage over current protection/ storage over voltage protection value. The operation method is similar to storage output current value setting. Press encoder potentiometer to return, and the data will be automatically saved.

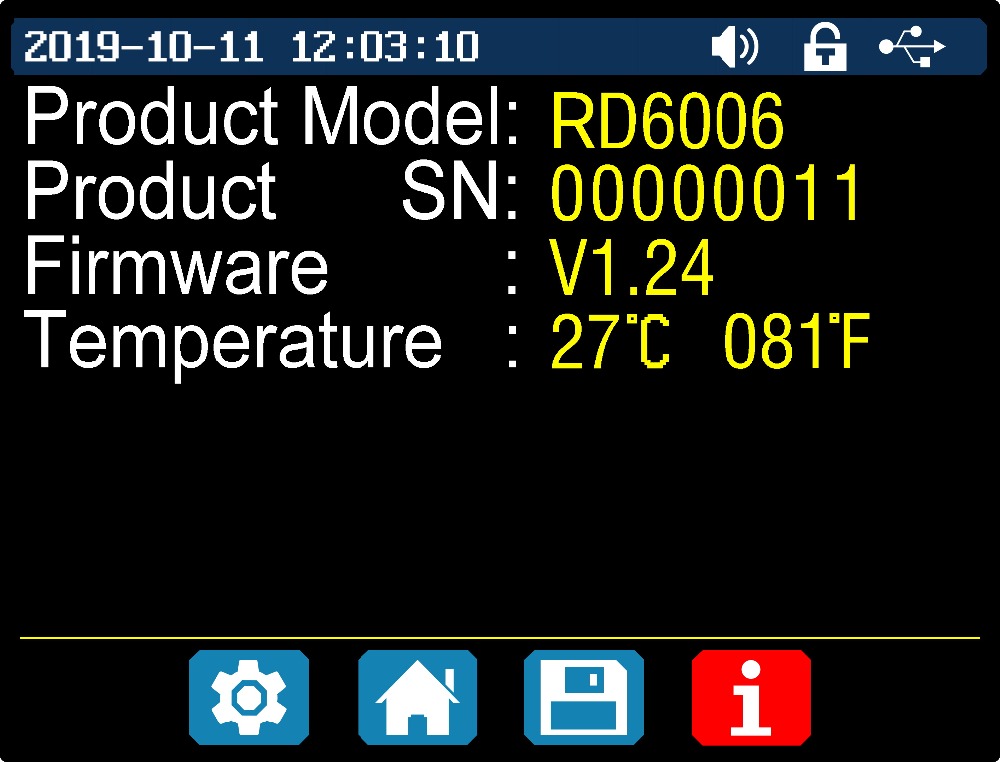

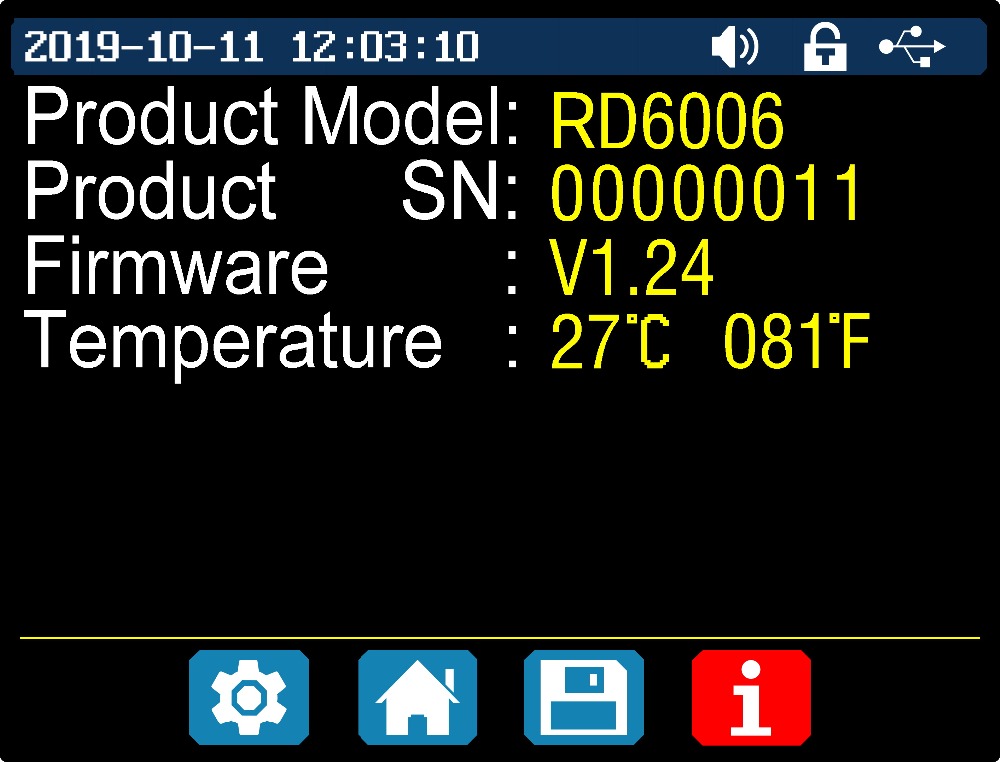

1.3.2.8 System Information

You can press SHIFT + MENU to enter the system setting menu, and then press the right button three times to enter the system information menu as shown above. You can view the SN number, firmware version and system temperature here.

Android APP Instruction

IOS APP Instruction can be found in the PDF file

3.1 Mobile Phone APP installation

Note:This product mobile APP function only supports Android 5.0 system or above. During the APP installation process, it will apply for location service. Please agree and turn on the location service. After downloading the mobile APP zip-file, please install the APP in file manager.

Don’t install or remove Wi-Fi module when the power is on, or else it will be damaged.This instruction is made for version 1.0.3, there will be little difference between different versions, we do recommend you to download the latest App for better experience.

3.1.1 APP download:

You can download the RD6006 APP zip-file in this URL:https://drive.google.com/open?id=17V-JWHvqMF-NuWSznEiJ4RKrnn_Pkt5v

3.2 InstallationIntroduction

After the installation, you can see the icon as shown below:

3.2.1 APP Start-up

Click the APP icon, After the APP starts, it will automatically detect whether there is a updated version, and it will remind you by popping the window.

3.2.2 APP Interface Display

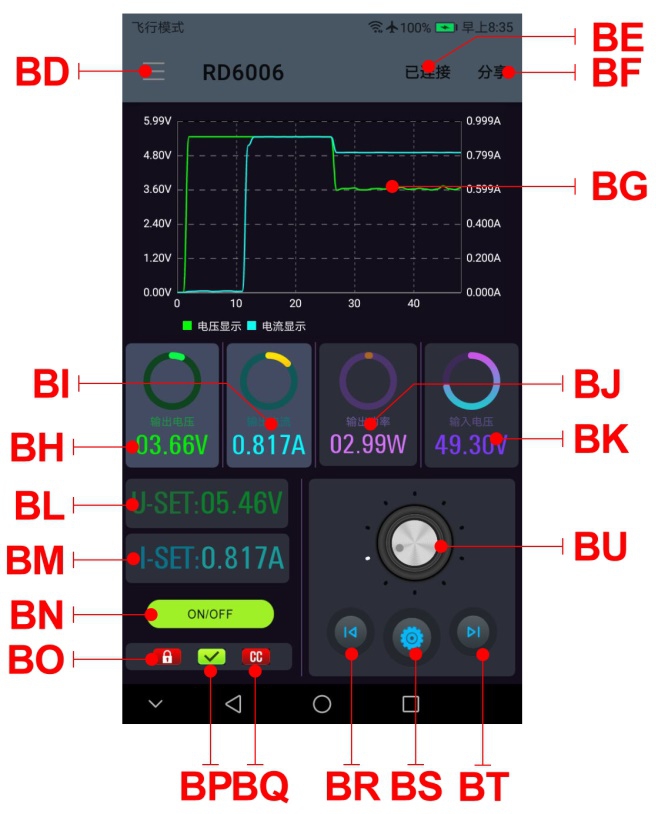

When updated to the latest version, the main interface of APP as shown below in Picture 1:

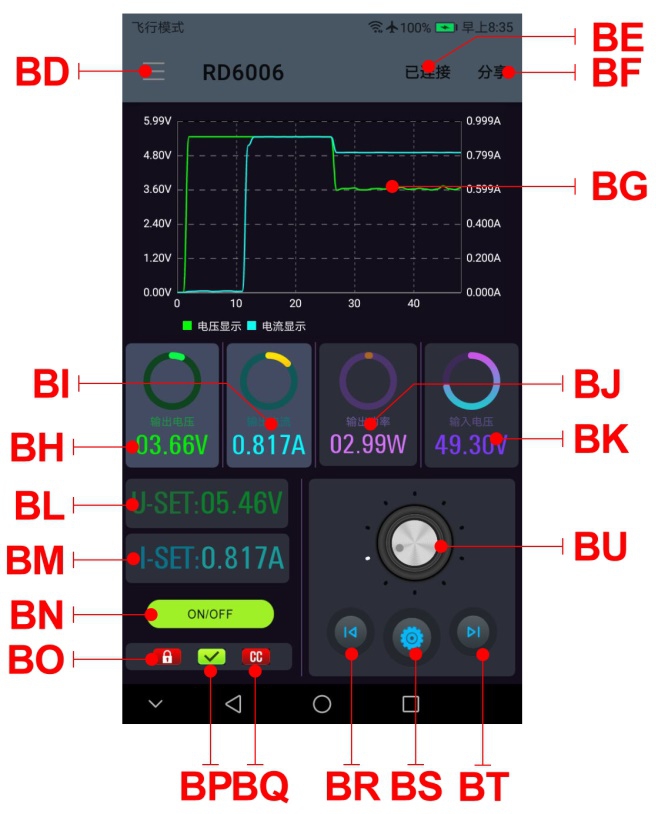

BD: call out/ shut down sidebar

BE: connection button

BF: export data to mobile phone folder (Mobile phone memory or SD card root directory, repeated writing, can directly generate graphs in Excel), and can share files to other APP.

| BG: voltage and current curve | BH: actual output voltage |

| BI: actual output current | BJ: output power |

| BK: input voltage | BL: preset voltage value |

| BM: preset current value | BN: ON/OFF switch |

| BO: keypad lock indication | BP: protection status indication |

| BQ: constant voltage/ constant current status | BR: move the cursor to the left |

| BS: settings | BT: move the cursor to the right |

| BU: setting wheel | |

3.2.3 APP Connection and Operation

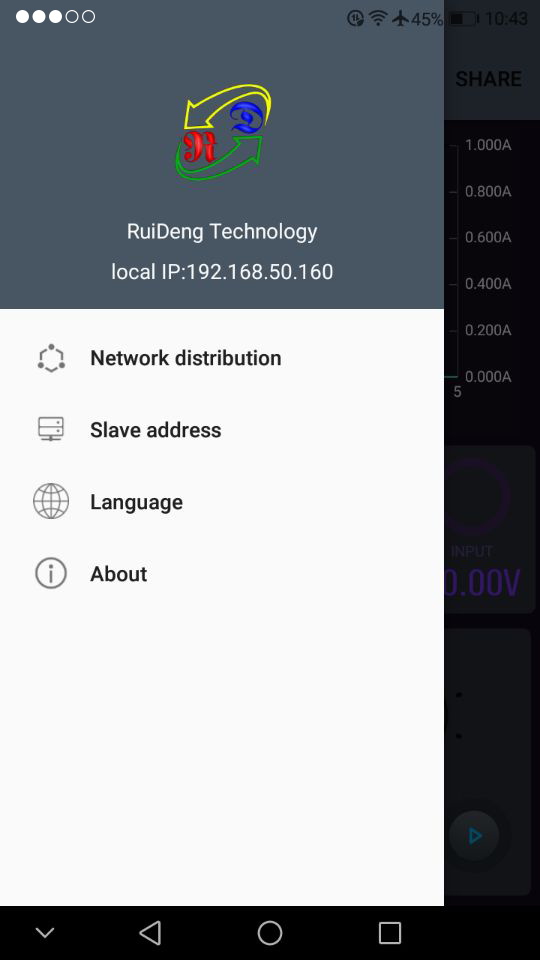

3.2.3.1 Network Distribution

| | |

| Picture 3 | Picture 4 |

| | |

| Picture 5 | Picture 6 |

| | |

| Picture 7 | Picture 8 |

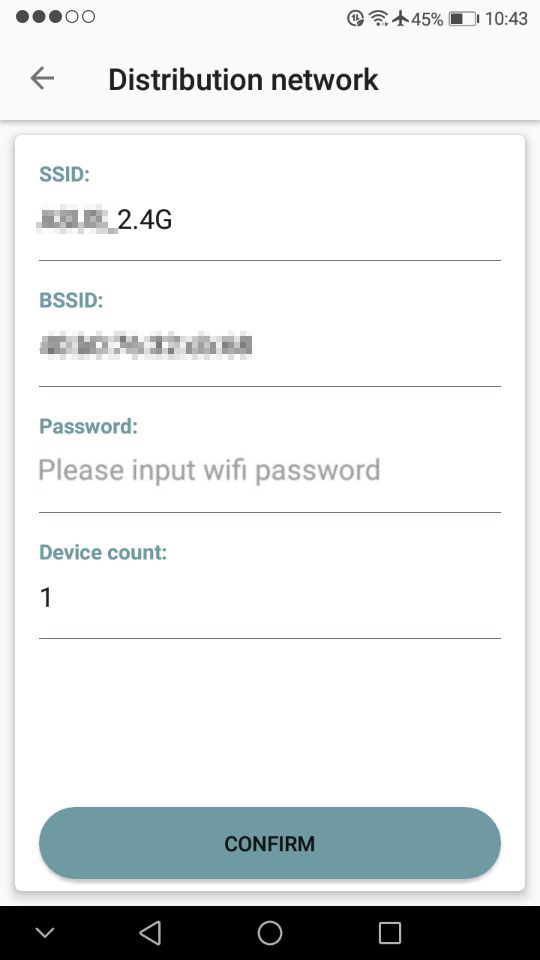

Connect Wi-Fi for the first time, the RD6006 and the mobile phone are placed close to the 2.4G router (the mobile phone must also be under the same 2.4G network, and the router must disable the AP isolation function).

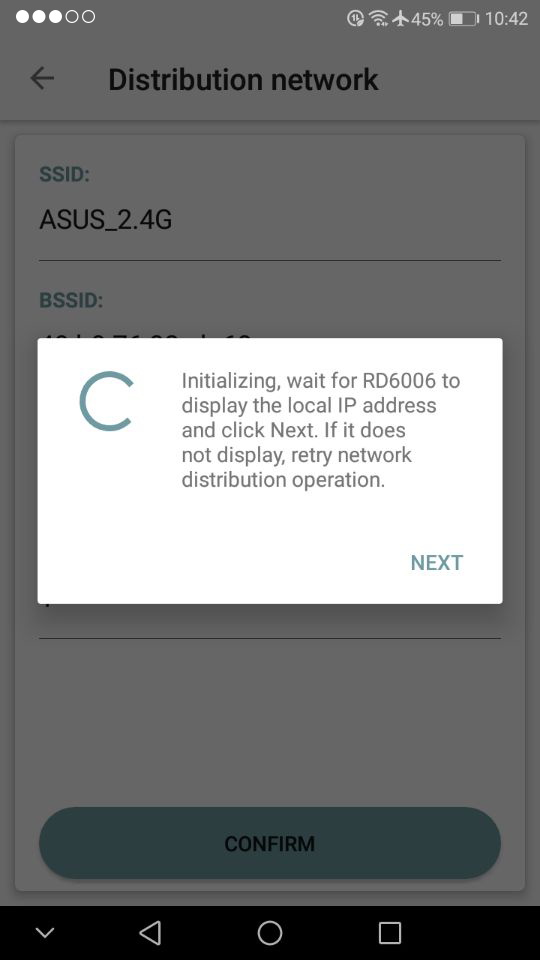

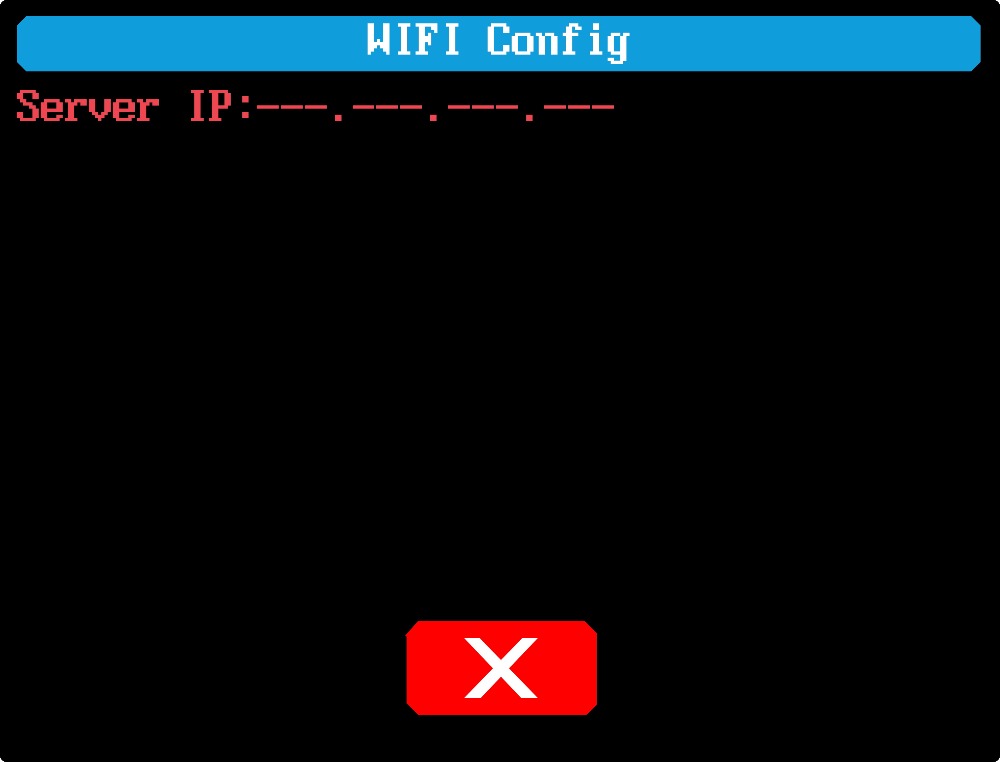

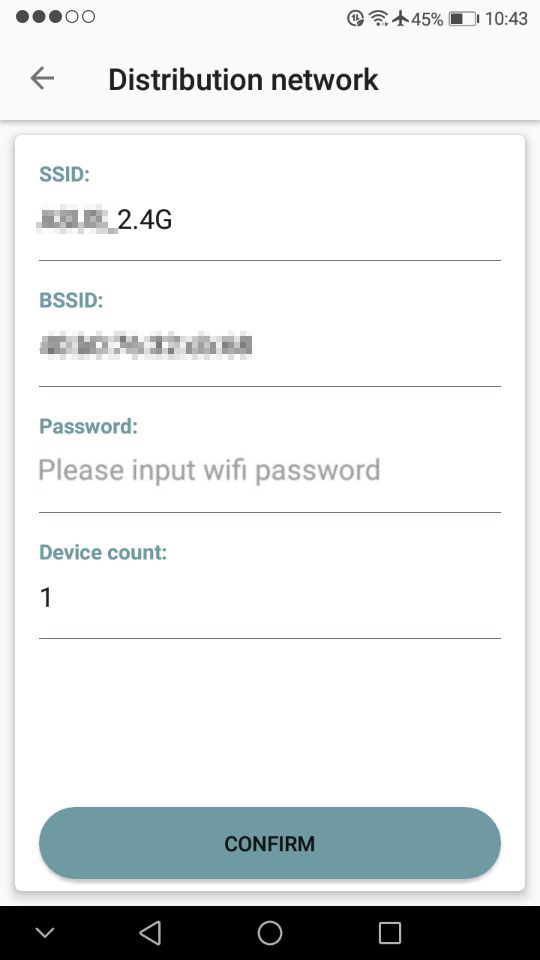

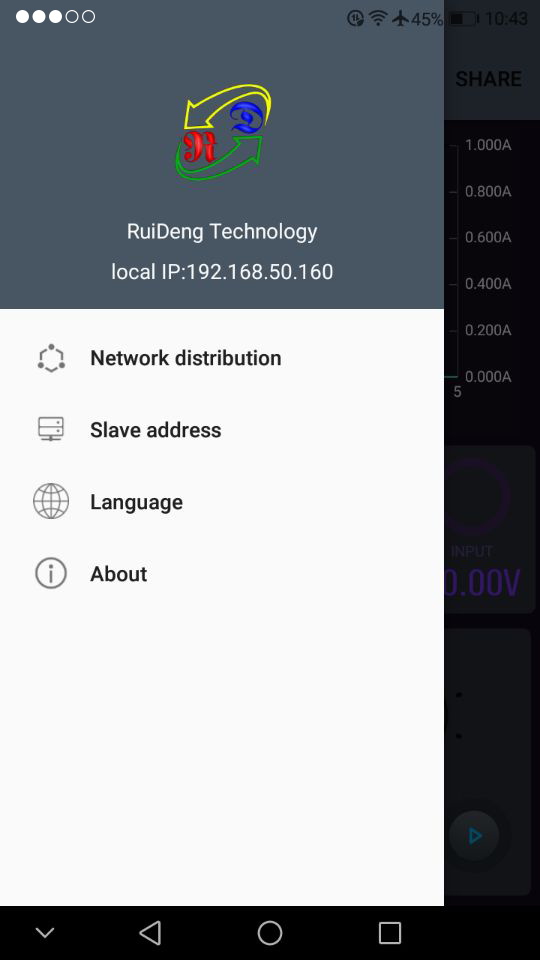

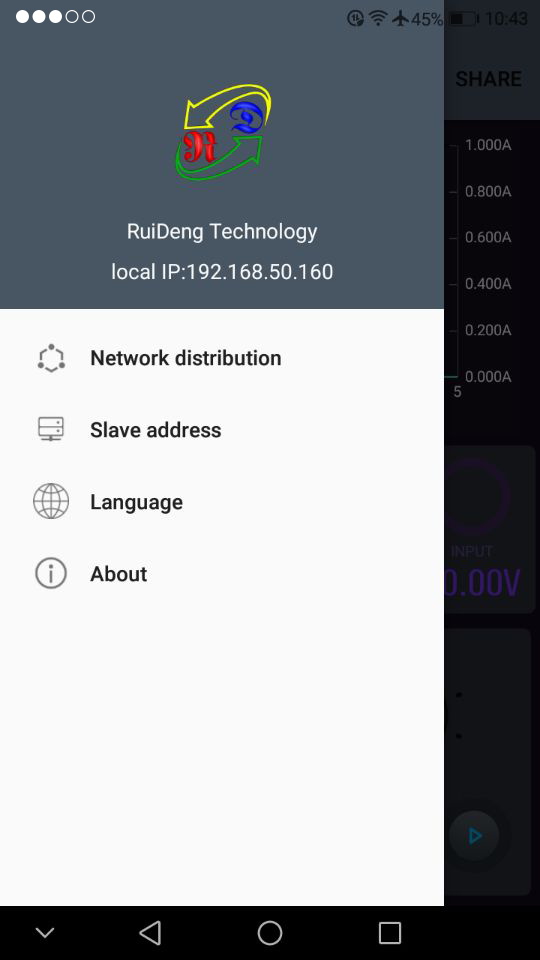

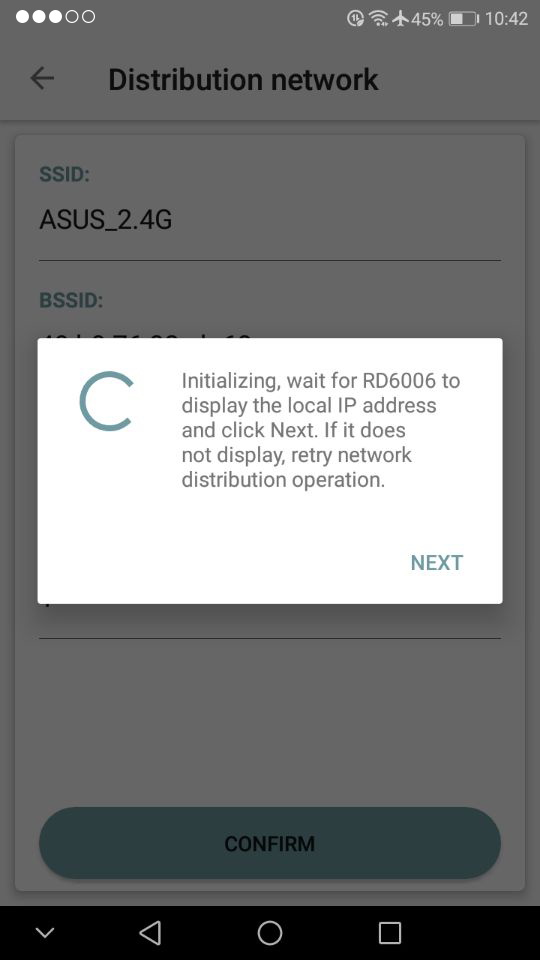

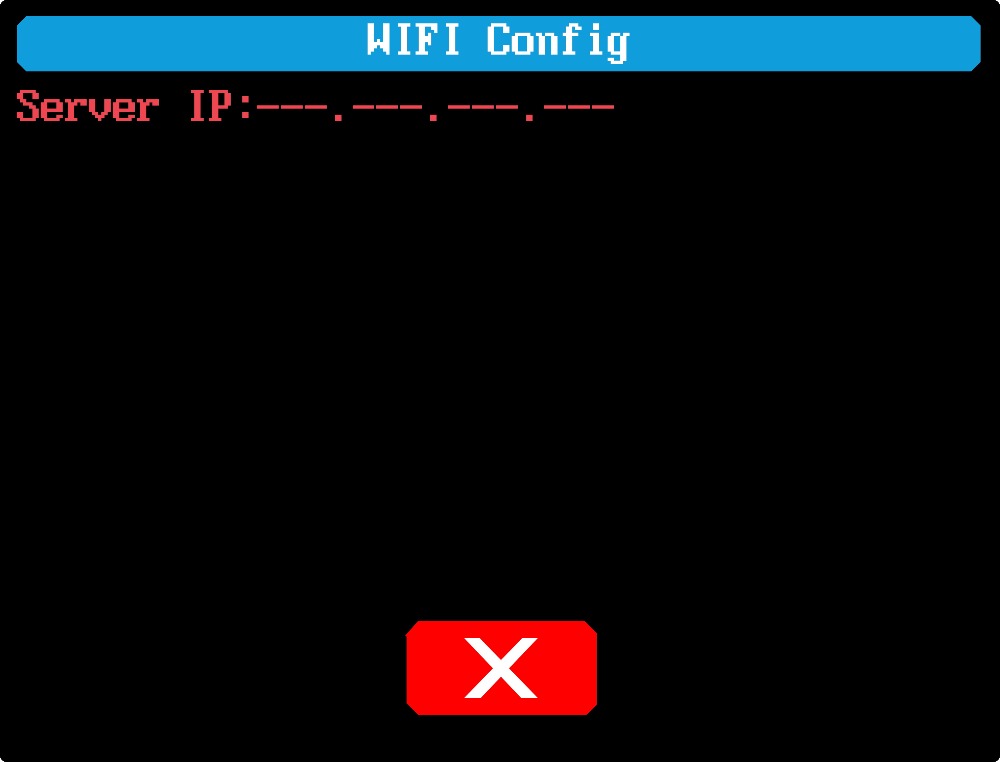

Set the communication interface to WIFI, restart, RD6006 will wait for the phone to connect as shown in Picture 5. Presses“BD”to call out the sidebar, clicks on the“Network distribution”as shown in Picture 3. There will be “Initializing...” displayed on the screen as shown in Picture 4.

3.2.3.2 Proper Wi-Fi Connection

When power on RD6006, it will connect Wi-Fi first, and then detect if it can be connected to APP as shown in Picture 8(the APP must already be running ). If the IP address of the phone has changed, you need to press the “left direction” button and then press “ENTER” button to reset the net, repeat 2.2.3.1 operation.

3.2.3.3 APP Functions

Click“BL”to set the output voltage, and use the wheel“BU”to adjust the value, the“BR”,“BT”to change the position of cursor, click“BS”to set the parameter. Click“BF”to exports the voltage-current curve to excel file, up to 24 hours document can be recorded.

NOTE:

1. There are many kinds of Android phone, so the user interface maybe different on some brand phones or different scales of the same brand.

2. Application permission requirements, allow the necessary permissions when the APP is installed (allow background running, using Bluetooth, operation on the folder, reading the application list, etc.) and also set the permissions of the APP after installation: Allow background running, never shut down when lock screen, allow self-starting(it is used to prevent the system from forcibly exiting the APP when recording data), etc.

PC Software InstallationandOperation Instruction

Requirement: the PC system must be Win 7 or above, and the computer has Internet connection.

This PC software is designed by Hangzhou Ruideng technology CO., LTD, it has no virus, if your anti-virus software prompts for a virus warning, please allow all its features, otherwise it will affect the normal operation of the software.

RD6006 digital power supply file download link:

https://drive.google.com/open?id=17V-JWHvqMF-NuWSznEiJ4RKrnn_Pkt5v

3.1 Software Installation

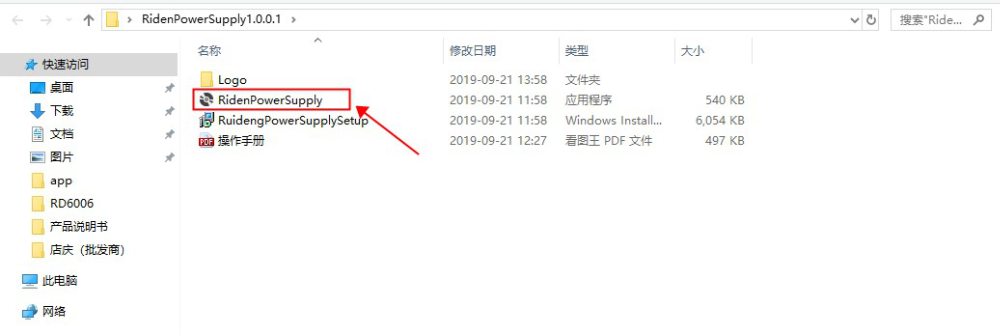

3.1.1 Unzip Files

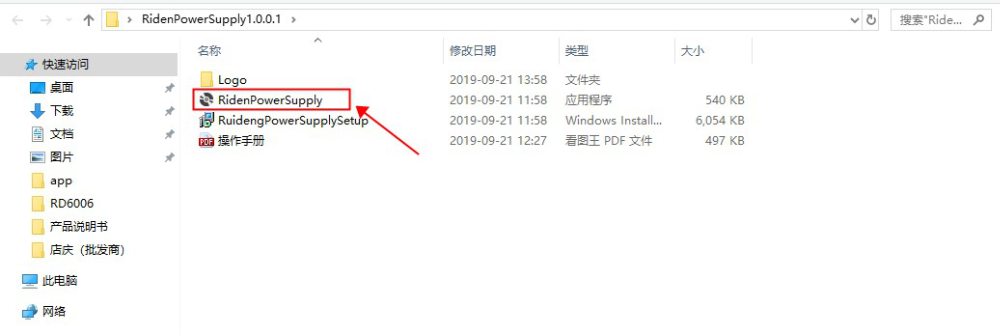

Unzip files and double-clickCH341SER.EXEfirst to install the driver, operate according to the installation, click [Next] until succeed.

3.1.2 Software Installation

Double click RidenPowerSupply.EXE to install the PC software, and it will automatically detect if.NET Framework 4.7.2is installed, if not,.NET Framework 4.7.2will be installed automatically.

1.1Core Function

·keypad + encoder potentiometer combination adjustment

·2.4 inch HD color screen

·Battery charging special interface

·Data quick storage & recall

·New PC software

·Wi-Fi connection, Phone APP control

1.2Panel Description

1.2.1Front panel

| A: Power button | B: Second function button |

| C: Quick storage button | D: Current/Over current protection value setting |

| E: Voltage/Over voltage protection value setting | F: Micro USB interface |

| G: Power supply output negative electrode Battery charging negative electrode | H: Battery charging positive electrode |

| I: Power supply output positive electrode | J: Output switch |

| K: encoder potentiometer/Cancel button | L: Direction button |

| M: Confirm button | N: keypad |

| O: Screen | |

1.2.2Back panel

| P: Input fuse | Q: Output fuse |

| R: Power source input interface | S: External temperature sensor interface |

| T: CR1220 battery socket | U: Communication module interface |

| V: Fan interface | |

NOTE:

Power source input interface must be connected to 6-70V constant DC power source. The external sensor cable (as shown on right) must be connected to the external temperature sensor interface. The fan interface cannot be connected to other fans. When the output current is higher than 4A or the system temperature higher than 45℃, the fan start to work, when the temperature is less than 40℃ and output current lower than 3.9A, the fan will stop working. When the system temperature is higher than 80℃, the output will be shut down because of OTP. CR1220 is the clock battery(Please prepare by yourself), communication interface is a special interface, please don’t connect to other modules or cables.

You can see the Wi-Fi module(RD6006-W contains) and RS-485 module in the picture below. If you need RS-485 for industrial batch test and it is not on sale now, if you want to use that, please contact us.

1.3Operation Introduction

After power-on, the boot image is displayed first, then enter the main page.

1.3.1MainPage

| W: Time | AF: Protection status indication |

| X: Button tune | AG: Battery charging indication |

| Y: Button lock status | AH: Battery related information display area |

| Z: Communication interface | AM: Input voltage |

| AA: Actual output voltage | AL: Output voltage preset value |

| AB: Actual output current | AK: Output current preset value |

| AC: Output power | AJ: Over voltage protection value |

| AD: Current data group | AI: Over current protection value |

| AE: Constant voltage Constant current status | |

1.3.2Operation Instruction

In the menu operation, the icon in red or cursor is the currently selected menu, the icon in blue is the unselected menu, pressENTERto confirm, press the encoder potentiometer to cancel or return, press the direction key to move the cursor or switch menu, rotate the encoder potentiometer to change the setting, the settings will be automatically saved when returning from the menu page. Press and hold the 0 button and power on to restore the factory settings, press and hold the 1 button and power on to restore the factory calibration value, press and hold ENTER and power on to enter the boot mode.

1.3.2.1Battery ChargingFunctionIntroduction

After power-on, at battery related information display area, external temperature, capacity and energy will loop display. When there is output current: capacity, energy automatically Accumulated, and automatically cleared after shutdown.

The green terminal is connected to the positive pole of the battery, and the black terminal is connected to the negative pole of the battery. After the battery is correctly connected, the battery charging indicator turns red and the battery is connected. Press ON/OFF to start charging, the battery charging indicator turns green. When the actual output current is lower than 10mA, the output will be shut down automatically. Battery with protection board may not be charged. The charging voltage and current should be set on your own.

It is strongly recommended to use the original charger to charge the battery. There is a risk of fire and explosion during the charging process. Non-professionals should not operate.

1.3.2.2Main Page Output Voltage and Output Current Setting

Press “I-SET”button to set the output current value, you can use encoder potentiometer to adjust the output value directly, press the direction button to move the cursor. Of course you can use keypad to set the value, and press “ENTER” to confirm. If you set the wrong value, you can press encoder potentiometer to cancel.

Press “V-SET”button to set the output voltage value, the operation method is similar to output current setting.

Press“SHIFT”+ “I-SET”button or“SHIFT”+ “V-SET”button to set the over current protection/ over voltage protection value. The operation method is similar to output current setting.

M0 is the default data group when RD6006 is powered on, manually modify the settings and automatically remember to M0 after confirmation.

1.3.2.3 Data Group Quick Storage and Call out

Press“MEM”+keypad button 1-9, you can store the output voltage value, output current value, over voltage protection value, over current protection value into the corresponding data group(as shown above), then press“ENTER”to confirm, or press the encoder potentiometer to cancel.

Press“SHIFT”+keypad button 1-9 to quick call out the saved data(as shown above). Press“ENTER”to confirm, or press the encoder potentiometer to cancel.

1.3.2.4 Keypad lock and unlock

Press“SHIFT”+”LOCK”to lock or unlock the keyboard. And the keypad will be automatically locked when communication starts, there will be

displayed on the top(can not unlock manually ), and the keypad will be automatically unlocked when the connection disconnected manually, there will be

displayed, the keypad will be automatically unlocked when the connection disconnected abnormally, and the power off button can be used when the keypad is locked.

1.3.2.5 System Setting

Press“SHIFT”+”MENU”to enter the system setting menu as shown on the right, press“ENTER”to enter the menu, press direction button to select option, the option in red is the option be chosen, rotate the encoder potentiometer to change setting.

Turn on the “Call OK”, a confirmation window will pop up when you quick call out a data group. If you turn it off, the setting values will be modified directly when you call out a data group.

Turn on the“Call out”, the output will be turn on automatically when you call out a data group. If you turn it off, the output will keep the previous status.

Turn on the“Power On”,it will turn on the output automatically when start. If you turn it off, the output will keep OFF status when started.

Turn on the“Beeper”,you will hear button tune when press the button, and there will be

on the top. If you turn it off, there will not be button tune when press the button, and there will be

on the top.

Turn on the“Logo”, it will display Logo first and then enter the main page when boot RD6006. If you turn it off, you will enter the main page directly.

The system language supports Simplified Chinese and English for the time being; the screen brightness can be set from level 0 to level 5; The communication interface can be set to USB, Wi-Fi or TTL,USBinterface is the Micro-USB interface on the front panel interface, you can see the

on the top when communication starts.Wi-Fiinterface is the Wi-Fi module connected to the communication interface, you can see the

on the top when communication starts (connect mobile phone by Wi-Fi, but you need to choose Wi-Fi interface first, Wi-Fi module can not be installed or removed when RD6006 is powered on),TTLis not available for the time being; When the interface is changed, you need to reboot RD6006 to apply the modification. The baud rate can be set 9600/19200/38400/57600/115200 under USB mode; The Baud rate under Wi-Fi is fixed at 115200. Device address can be set from 001-255. You can set the date and time by rotating the encoder potentiometer, the setting will be saved immediately after modification. Please do not set a wrong time, it may cause the date to not be automatically accumulated. Press the encoder potentiometer to return, and the set value will be saved automatically.Measureis the refresh rate of read back voltage and current in the main page, you can set it to low, middle and high. Press encoder potentiometer to return and it will be automatically saved.

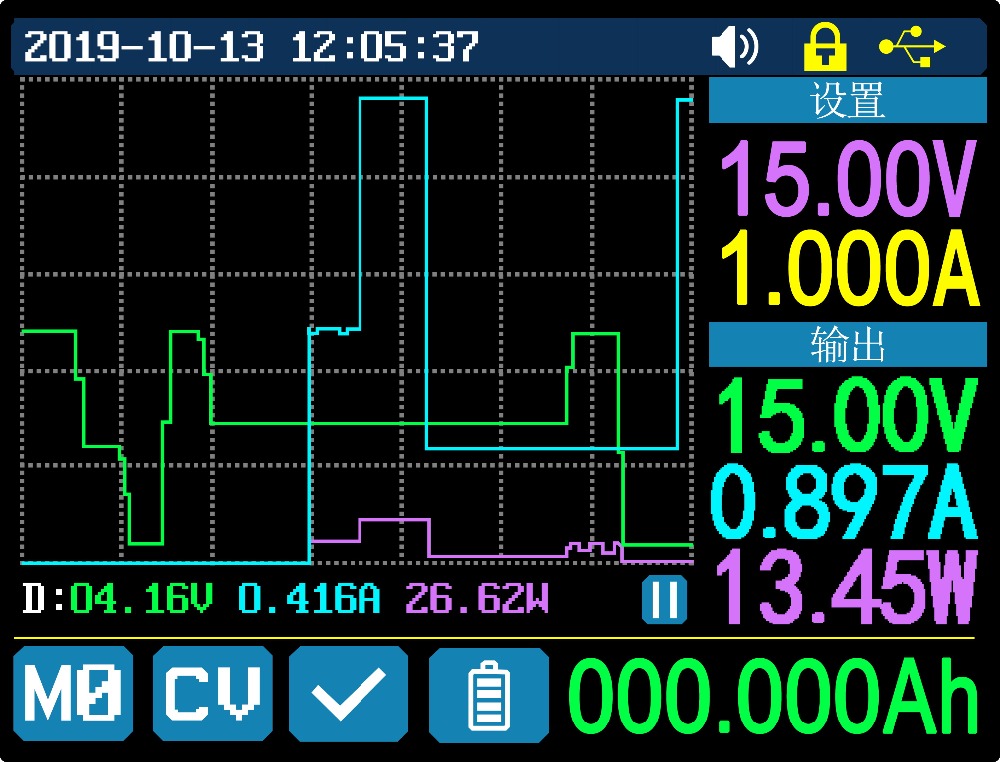

1.3.2.6 Main Page Style Setting

You can press SHIFT + MENU to enter the system setting menu, and then press the right button to enter the main page style setting menu as shown above. Press ENTER and then use direction button to set classic style or curve style. The pattern in red is the style be chosen. The classic style is the system default style, and the large font shows the voltage, current and power. The curve style is as shown above, the color of the three curves corresponds to the output voltage, current and power. D is the scale of the ordinate, Press“ENTER”to start or pause the curve, and the rotate encoder potentiometer to scale the ordinate of the curve.

1.3.2.7 Storage Data Setting

You can press SHIFT + MENU to enter the system setting menu, and then press the right button twice to enter the data storage setting menu as shown below, press ENTER to enter the setting menu, the icon in red is the chosen data group, press the direction button to select data group number. Press “I-SET”button to set the storage output current value, then rotate the encoder potentiometer the adjust the output value, press the direction button to move the cursor. You can also set the value with keypad, press ENTER to confirm. If you set the wrong value, you can press the encoder potentiometer to cancel. Press “V-SET”button to set the storage output voltage value, the operation method is similar to storage output current setting.

Press“SHIFT”+ “I-SET”button or“SHIFT”+ “V-SET”button to set the storage over current protection/ storage over voltage protection value. The operation method is similar to storage output current value setting. Press encoder potentiometer to return, and the data will be automatically saved.

1.3.2.8 System Information

You can press SHIFT + MENU to enter the system setting menu, and then press the right button three times to enter the system information menu as shown above. You can view the SN number, firmware version and system temperature here.

Android APP Instruction

IOS APP Instruction can be found in the PDF file

3.1 Mobile Phone APP installation

Note:This product mobile APP function only supports Android 5.0 system or above. During the APP installation process, it will apply for location service. Please agree and turn on the location service. After downloading the mobile APP zip-file, please install the APP in file manager.

Don’t install or remove Wi-Fi module when the power is on, or else it will be damaged.This instruction is made for version 1.0.3, there will be little difference between different versions, we do recommend you to download the latest App for better experience.

3.1.1 APP download:

You can download the RD6006 APP zip-file in this URL:https://drive.google.com/open?id=17V-JWHvqMF-NuWSznEiJ4RKrnn_Pkt5v

3.2 InstallationIntroduction

After the installation, you can see the icon as shown below:

3.2.1 APP Start-up

Click the APP icon, After the APP starts, it will automatically detect whether there is a updated version, and it will remind you by popping the window.

3.2.2 APP Interface Display

When updated to the latest version, the main interface of APP as shown below in Picture 1:

BD: call out/ shut down sidebar

BE: connection button

BF: export data to mobile phone folder (Mobile phone memory or SD card root directory, repeated writing, can directly generate graphs in Excel), and can share files to other APP.

| BG: voltage and current curve | BH: actual output voltage |

| BI: actual output current | BJ: output power |

| BK: input voltage | BL: preset voltage value |

| BM: preset current value | BN: ON/OFF switch |

| BO: keypad lock indication | BP: protection status indication |

| BQ: constant voltage/ constant current status | BR: move the cursor to the left |

| BS: settings | BT: move the cursor to the right |

| BU: setting wheel | |

3.2.3 APP Connection and Operation

3.2.3.1 Network Distribution

| | |

| Picture 3 | Picture 4 |

| | |

| Picture 5 | Picture 6 |

| | |

| Picture 7 | Picture 8 |

Connect Wi-Fi for the first time, the RD6006 and the mobile phone are placed close to the 2.4G router (the mobile phone must also be under the same 2.4G network, and the router must disable the AP isolation function).

Set the communication interface to WIFI, restart, RD6006 will wait for the phone to connect as shown in Picture 5. Presses“BD”to call out the sidebar, clicks on the“Network distribution”as shown in Picture 3. There will be “Initializing...” displayed on the screen as shown in Picture 4.

3.2.3.2 Proper Wi-Fi Connection

When power on RD6006, it will connect Wi-Fi first, and then detect if it can be connected to APP as shown in Picture 8(the APP must already be running ). If the IP address of the phone has changed, you need to press the “left direction” button and then press “ENTER” button to reset the net, repeat 2.2.3.1 operation.

3.2.3.3 APP Functions

Click“BL”to set the output voltage, and use the wheel“BU”to adjust the value, the“BR”,“BT”to change the position of cursor, click“BS”to set the parameter. Click“BF”to exports the voltage-current curve to excel file, up to 24 hours document can be recorded.

NOTE:

1. There are many kinds of Android phone, so the user interface maybe different on some brand phones or different scales of the same brand.

2. Application permission requirements, allow the necessary permissions when the APP is installed (allow background running, using Bluetooth, operation on the folder, reading the application list, etc.) and also set the permissions of the APP after installation: Allow background running, never shut down when lock screen, allow self-starting(it is used to prevent the system from forcibly exiting the APP when recording data), etc.

PC Software InstallationandOperation Instruction

Requirement: the PC system must be Win 7 or above, and the computer has Internet connection.

This PC software is designed by Hangzhou Ruideng technology CO., LTD, it has no virus, if your anti-virus software prompts for a virus warning, please allow all its features, otherwise it will affect the normal operation of the software.

RD6006 digital power supply file download link:

https://drive.google.com/open?id=17V-JWHvqMF-NuWSznEiJ4RKrnn_Pkt5v

3.1 Software Installation

3.1.1 Unzip Files

Unzip files and double-clickCH341SER.EXEfirst to install the driver, operate according to the installation, click [Next] until succeed.

3.1.2 Software Installation

Double click RidenPowerSupply.EXE to install the PC software, and it will automatically detect if.NET Framework 4.7.2is installed, if not,.NET Framework 4.7.2will be installed automatically.

3.2 Software Operation

3.2.1 Installation Succeed

Double clickRiden Power Supplyon the desktop to enter the PC software.

3.2.2 PC Software Operation Instruction

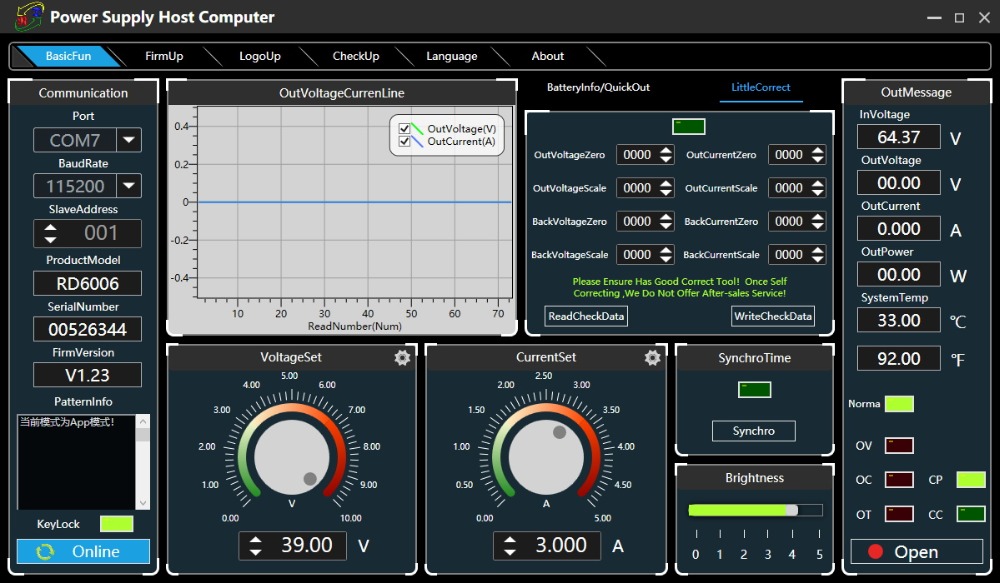

Choose the right communication port, baud rate, slave address(default 001), click“CONNECT”to start communication. If the communication succeeds, the power supply button will be locked automatically, the buttons will automatically unlock after 3 seconds of accidental disconnection, and the“CONNECT”turns to“DISCONNECT”; Click“ON”to turn on the output of the power supply, and it will turn to“OFF”.

3.3 FunctionsIntroduction

The PC software interface mainly has basic functions, firmware upgrade, Logo upgrade, version update detection and language setting...

BF: Voltage-Current Curve

BG: Battery information/Data Group Quick Call Out

BH: Calibration

BI: Input Voltage

BJ: Actual Output Voltage

BK: Actual Output Current

BL: Actual Output Power

BM: System Temperature(℃)

BN: System Temperature(℉)

BO: Constant Voltage/ Constant Current Status

BP: Protection Status Indication

BQ: Screen Brightness Setting

BR: Synchronize System Time

BS: Output Current Preset value

BT: Output Voltage Preset value

BU: Firmware Version

BV: Serial Number

BW: Product Model

3.3.1 BasicFunctions

The basic functions of PC software: voltage/current preset, data group quick call out, calibration fine tuning, brightness setting, voltage and current curve exporting. You can rotate the wheel or type numbers to set the voltage and current, the graph above the button shows the real-time voltage and current curve.

3.3.2 Firmware Upgrade

Press and hold “ENTER” and power on RD6006, enter the boot mode, then connect it to computer, there will be “boot mode” in the mode information text box, then click“FirmUp”, a firmware upgrade prompt will pop up on the interface, and click “Upgrade Now” to upgrade. (You can upgrade the firmware under the APP mode, if it can not be started up normally, you should press and hold the“ENTER”button and power on, upgrade it under boot mode.)

During the firmware upgrade process, the interface is displayed as follows:

3.3.3CalibrationFineTuning

The calibration fine-tuning function needs to be operated by a professional electronic person who has more than five and a half multimeters. It will change the system setting, incorrect operation may exceed the hardware limit and cause damage, and the resulting damage is not covered by the warranty! The limit error of the product is generally much smaller than the nominal error, when the error is close to or even higher than the nominal error, you need to check if the measuring instrument is accurate.

Click“Calibration Fine Tuning”and enter the password “168168”, you can enter the Calibration Fine Tuning page(if you enter the password, By default you have accepted the above red letter agreement ). It can read the calibration data after connection, click the arrow to fine tuning the data. According to the linear function y=kx+b, the constant b is equivalent to the zero value, the slope k is equivalent to the proportional value, adjust this two values so that the the data will be close to the real value.

Set the output voltage at 1V, adjust the output voltage zero point to make the multimeter display close to 1V, then set the output voltage at 30V, adjust the output voltage proportional value to make the multimeter display close to 30V. In the same way you can set 0.1A and 3A output current to calibrate the the zero point and proportional value of the output current.

Set the output voltage at 1V and calibrate the actual output voltage zero point to make the actual output voltage displayed on RD6006 close to the value on multimeter. You can set 30V and calibrate the proportional value of actual output voltage. In the same way you can set 0.1A and 3A to calibrate the zero point and proportional value of the actual output current.(This section does not provide technical support. If you do not understand, please check the related information).

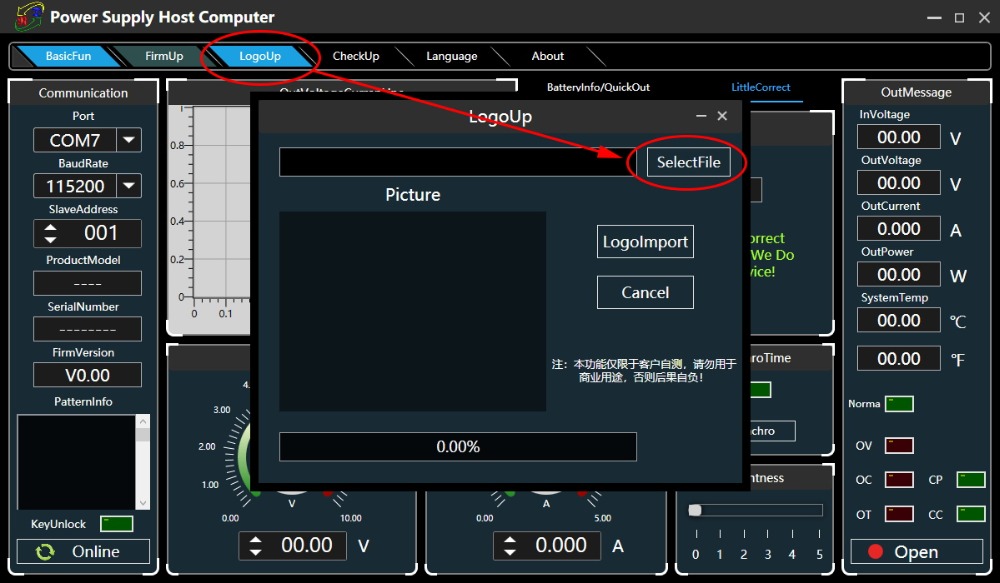

3.3.4Logo Update

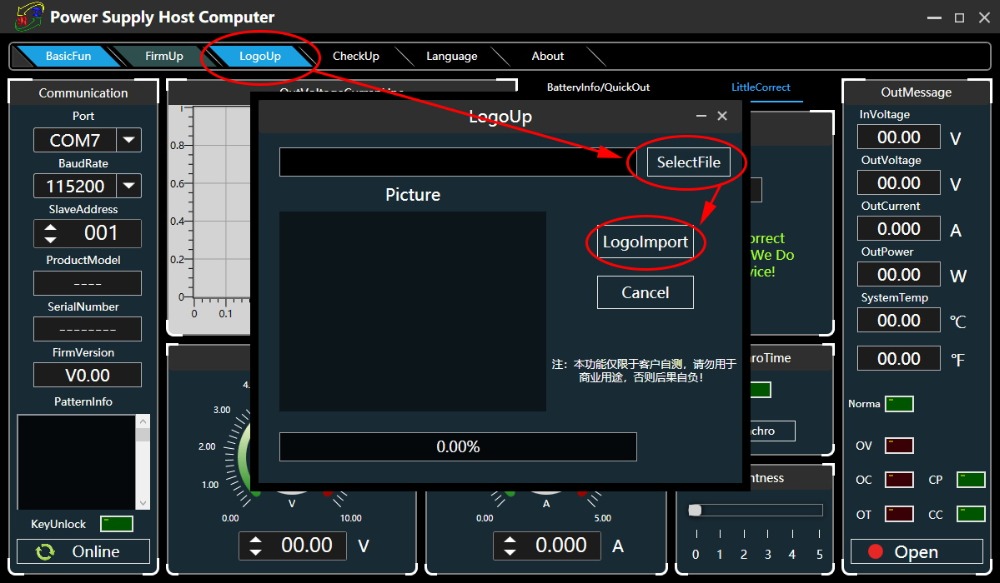

Click“LogoUp”, a Logo upgrade prompt will pop up on the page, please select a picture with a size of 320x240 and a resolution of 96dpi (At present, only fixed-size image updates can be used at the moment, and we will add new function that you can use any size image and the image will be cropped and imported later. Some logo samples can be tested in the installation package)

Click “LogoImport” and RD6006 will reboot automatically.

3.3.5Version Update Detection

Click“CheckUp”,the software will automatically detect if there is a new version, if so, a update prompt will pop up on the interface.

3.3.6Language Setting

Click“Language”, a language setting prompt will pop up on the interface, you can choose Simplified Chinese or English.

3.3.7About

Click“About”, you can check the version number, publish time and copyright Information.

1. Affected by the injection molding process, there are slight traces at the button holes of the shell. It can hardly be found in normal use. It can be found under the light (the shell is not crafts, don't be overly picky). as shown in picture 1,if you care, please don't buy this product

2. It is recommended to use fork terminal cables or lantern head cables as output cables, and you cannot use stackable connector(it may cause poor contact). Never insert the multimeter probes to the terminals(it will damage the terminals). as shown in picture 2

3.when the button light is on, when the surrounding environment is dark, it will be found that the adjacent buttons have weak light, normal use has no effect. as shown in picture 3