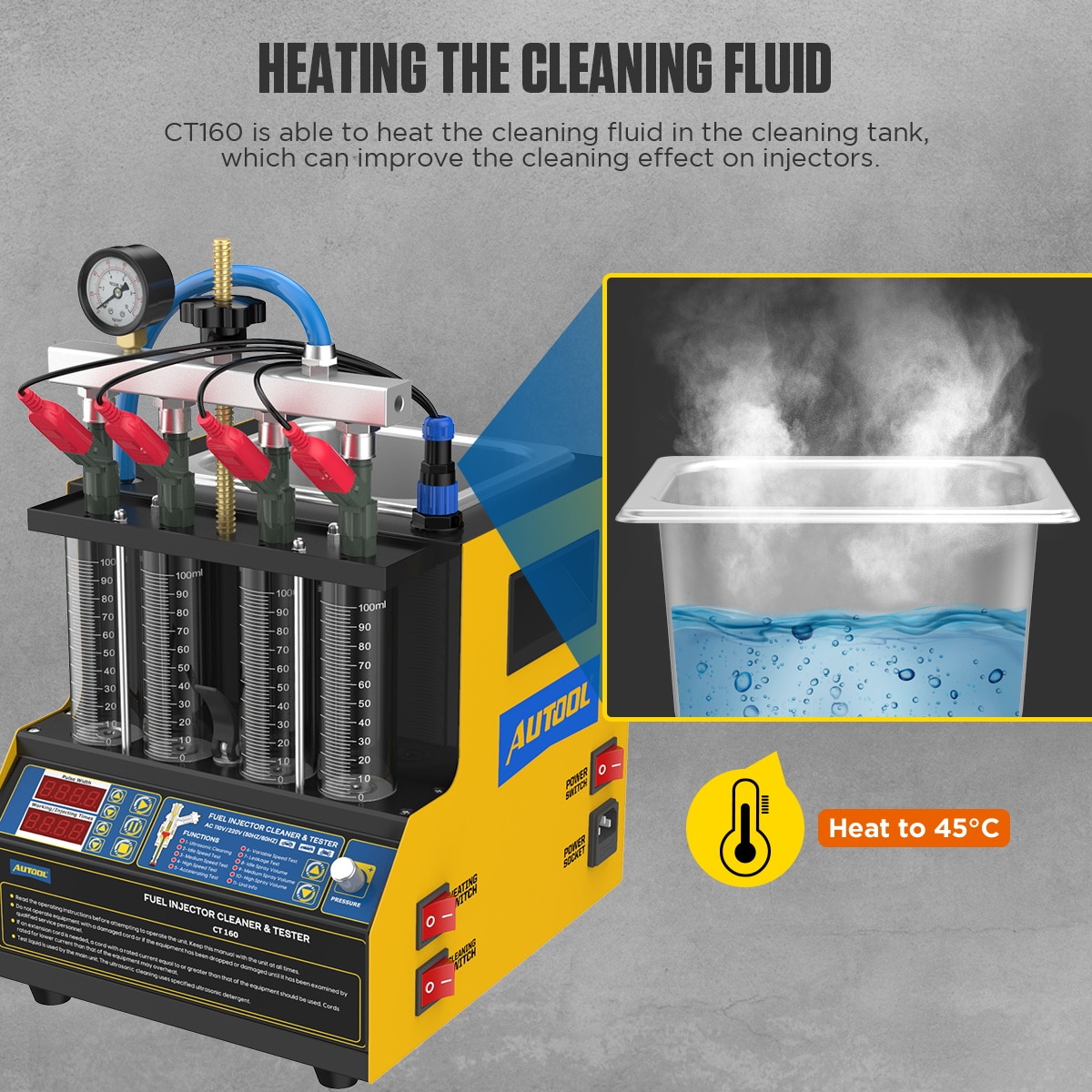

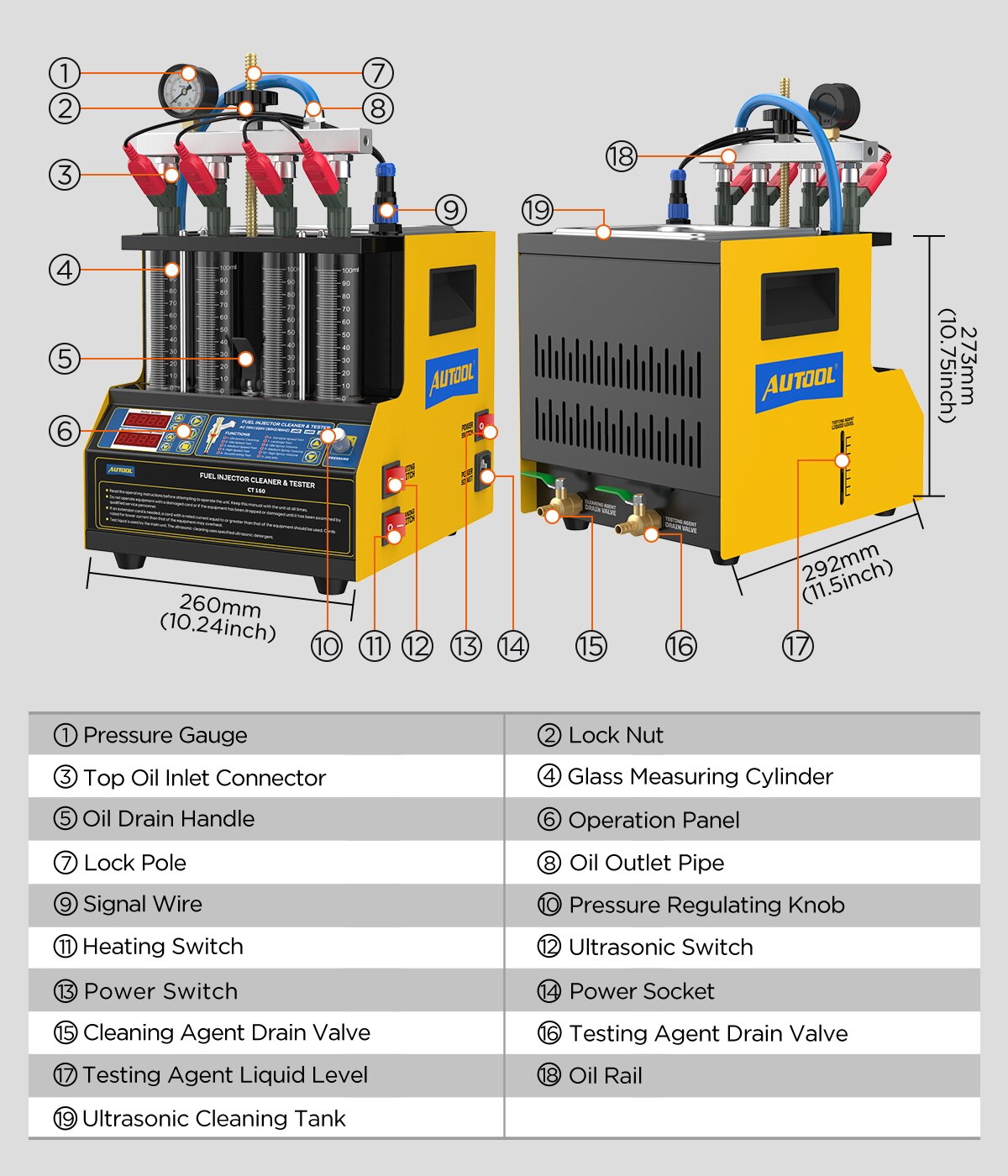

AUTOOL CT160 Car Fuel Injector Tester Heating Cleaner is a professional 4 cylinders auto fuel injector testing cleaning machine. It will help us clean and test the injectors of gasoline cars and motorcycles. Support for more cars and motorcycles.Can only be used to clean diesel fuel injectors.The cleaning fluid is 3M car injector cleaning fluid, and the test fluid is industrial alcohol.Its working voltage range is 110-230V and English control panel.

AUTOOL CT160 Car Fuel Injector Tester Heating Cleaner has been arranged for strict quality inspection before leaving the warehouse, and there will be no more defective products. The oil pump is working normally, please rest assured to buy. Feel free to contact me if you have any questions about the device. Thank you

Support for Audi,for Australia Ford,for Benz,for BMW,for Brilliance,for Chevrolet,for Chevy,for Chrysler,for Citroen,for Dacia,for Dadi,for Daewo,for Daihatsu,for Demo,for Fiat,for Ford,for GM,for Holden,for Honda,for Hyundai,for Isuzu,for Jaguar,for Kia,for Lancia,for Land Rover,for Mahindra,for Maruti,for Mazda,for Mitsubish,for Nissan,for Opel,for Peugeot,for Porsche,for Renault,for Romeo,for Rover,for Saab,for Seat,for Skoda,for Smart,for Subaru,for SUZUKI,for Tata,for Toyota,for Volvo,for VW,for Yamaha.

1.[Wide range of applications] :CT160 Car Fuel Injector Tester and Heating Cleaner have a good compatibility. Support for more cars and motorcycles to ‘clean’ and ‘test’ fuel injector. And also can be used to ‘clean’ diesel fuel injectors.

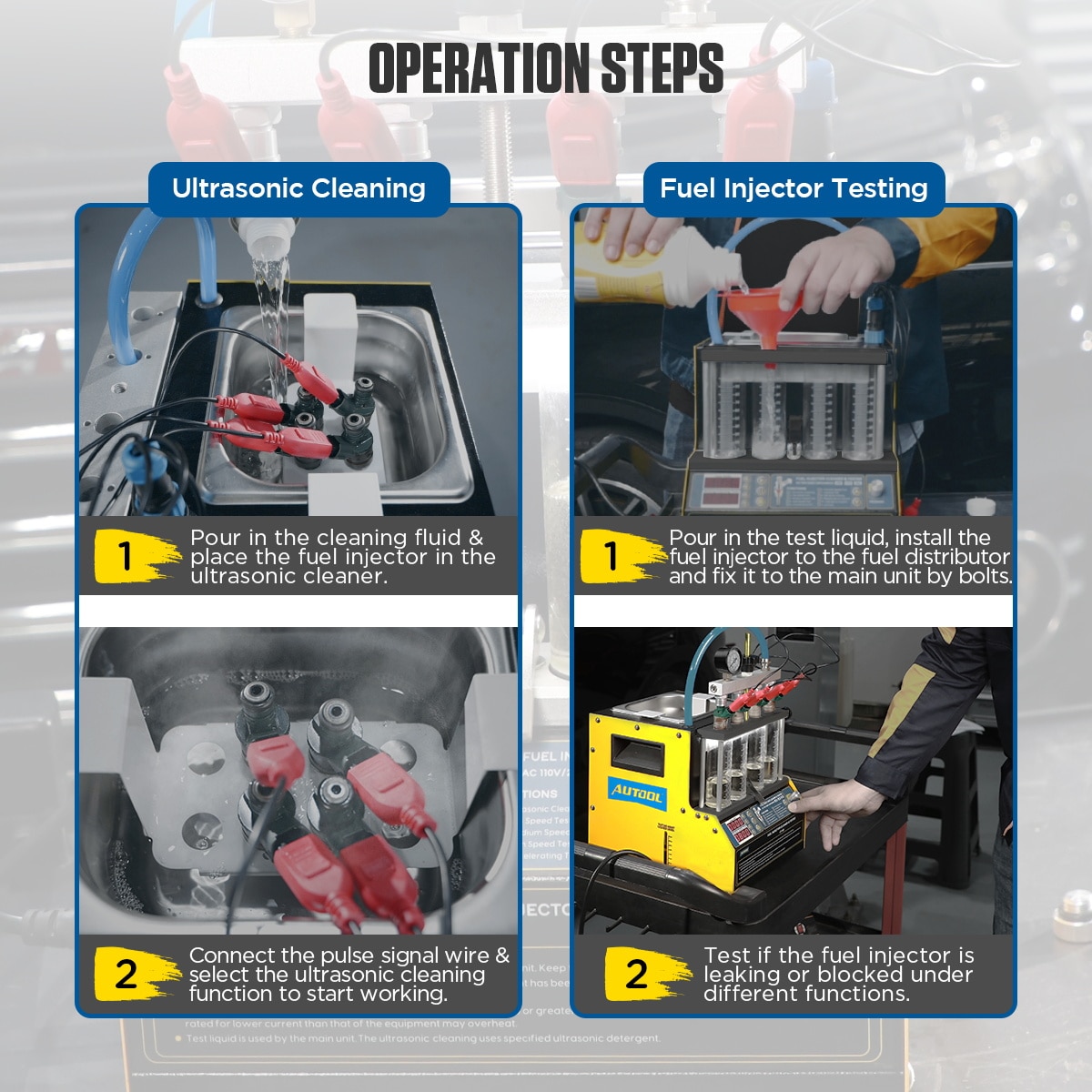

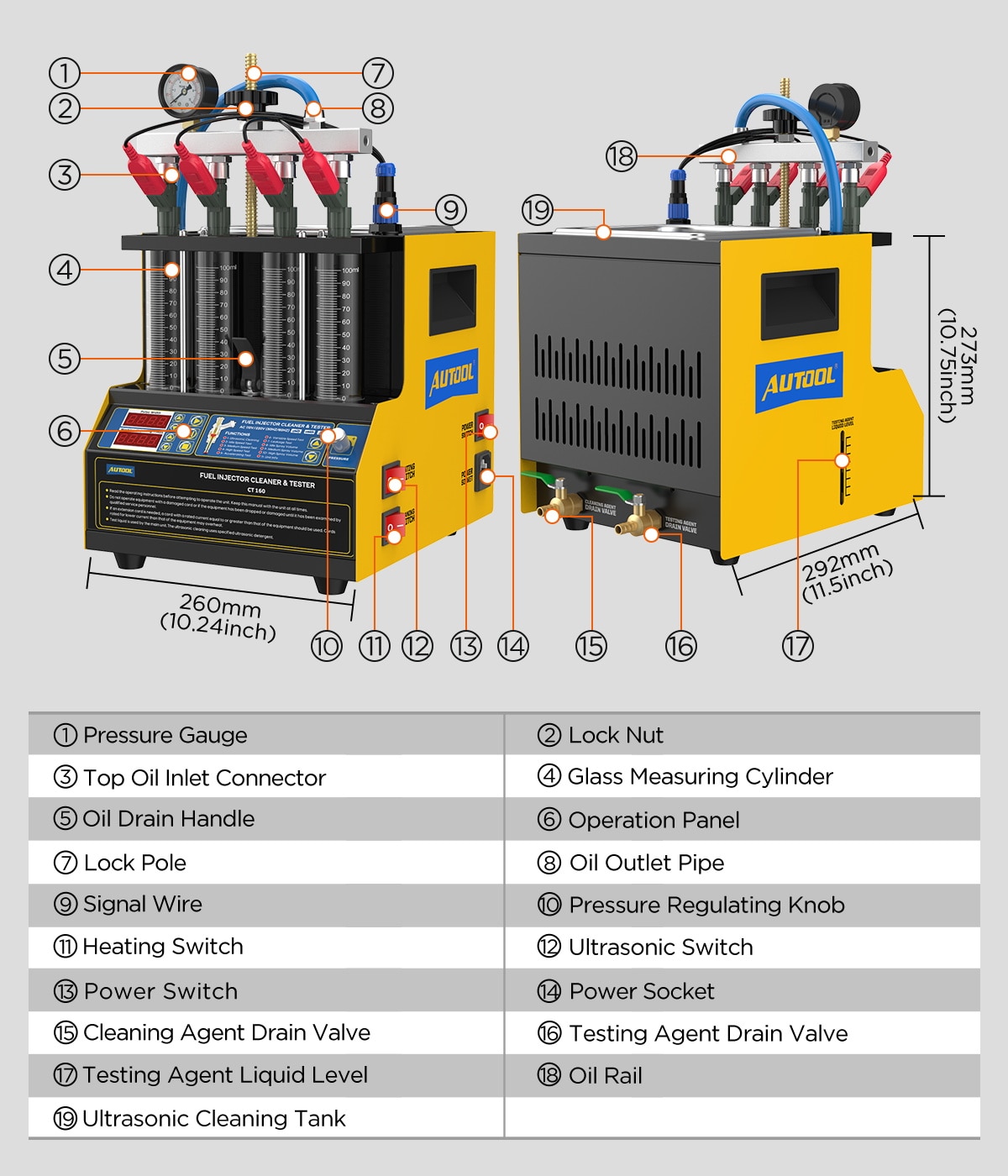

2.[Easy to operate ] :When cleaning, fix the car injector in the socket of the washing tank, add an appropriate amount of 3M cleaning fluid, and the cleaning can be completed after power on; when testing, fix the car injector in the oil separator and add it to the glass tube Industrial alcohol, the test can be completed after power on.

3.[Leading technology] :At present, only our company produces this portable and multi-functional automobile fuel injector cleaning and testing machine, and it has obtained a special patent.

4.[Safety]:Its working voltage range is 110-230V. When the machine is short-circuited, the fuse inside will automatically trip to shut down the running machine to prevent electric shock.

5.[3 year warranty]:For damage caused by non-human factors, we promise to resend parts for free within 3 years.

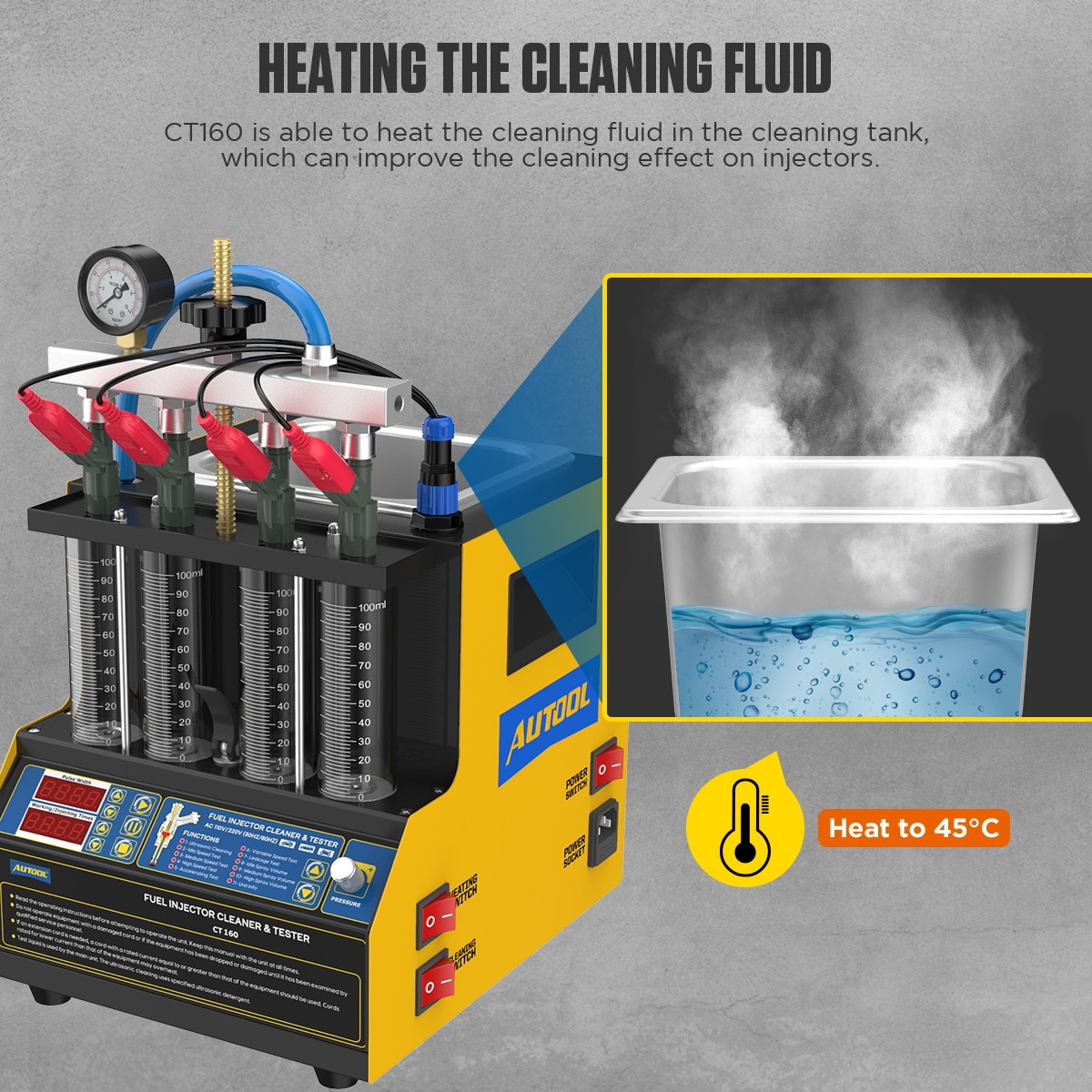

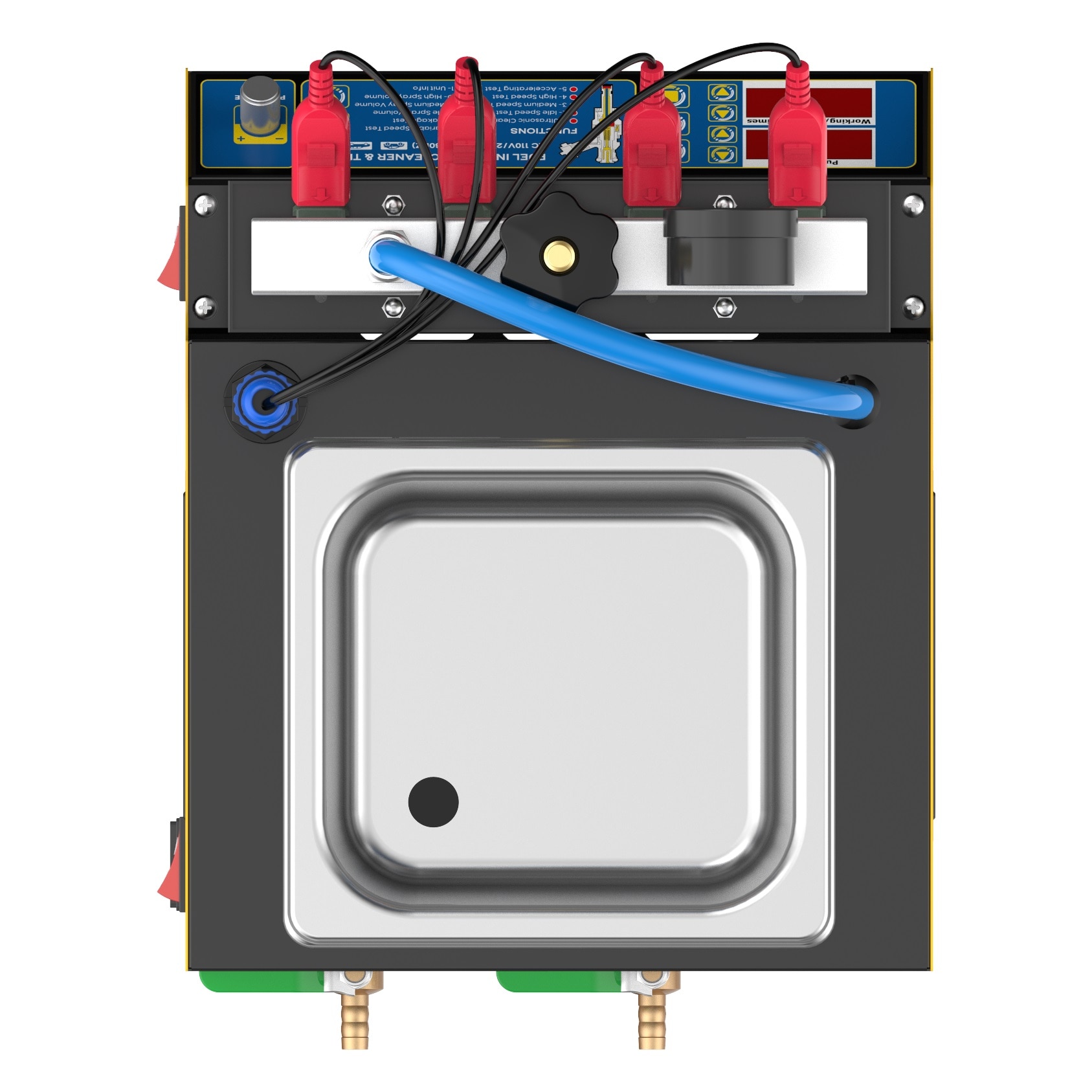

1.Clean injector's outside with cleaning liquid before open machine .Putting injectors in ultrasonic bathtub after the outside of injector are free of dirt.The cleaning fluid does not exceed the connection port of the pulse line.

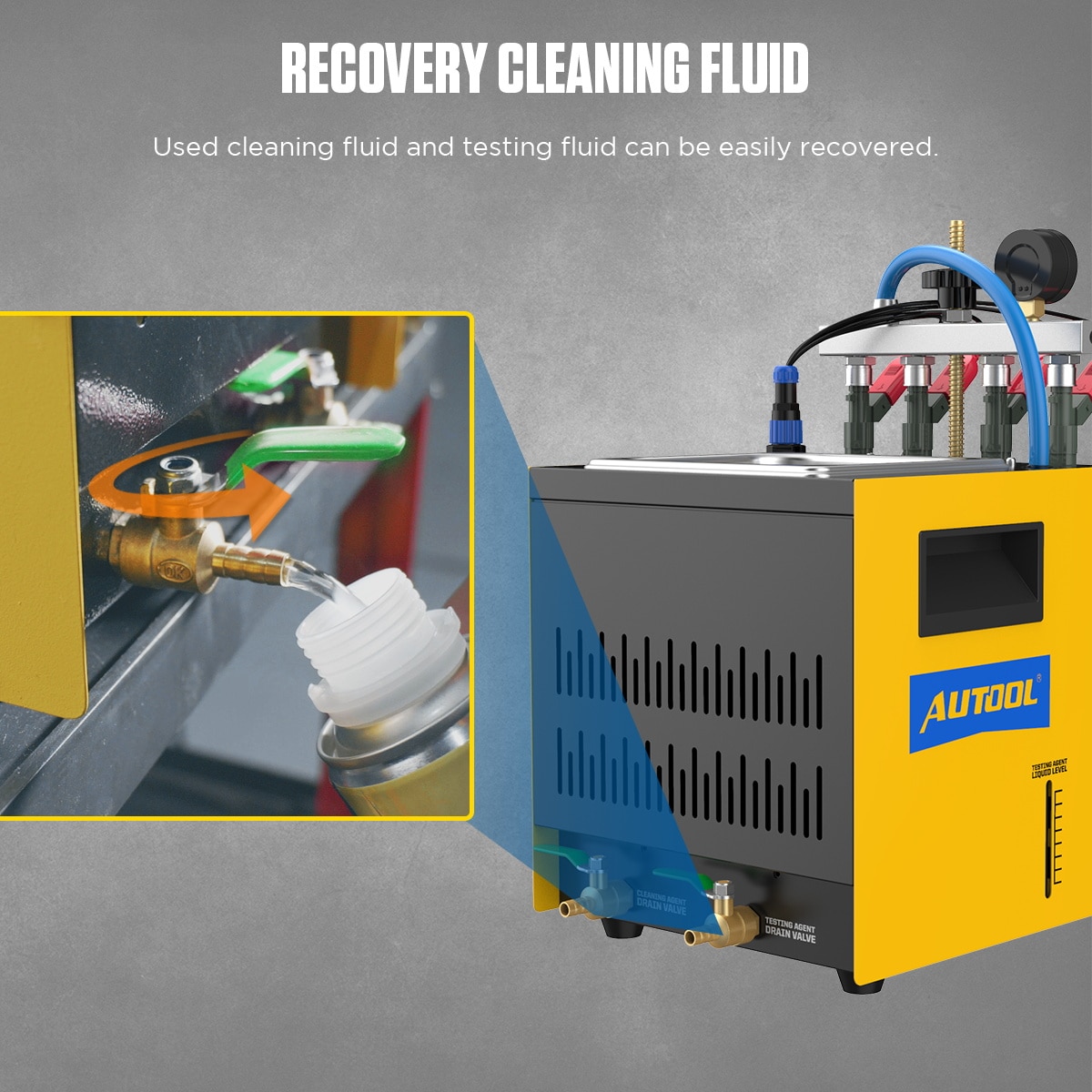

2.Turn on ultrasonic system allowing the ultrasonic energy to dislodge any particles build-up inside the injectors.After cleaning, the remaining cleaning fluid can be recycled.

3.Fixed injectors on main machine,testing injectors for resistance, shorts, and current draw.The test liquid can be added to the half of the glass tube.

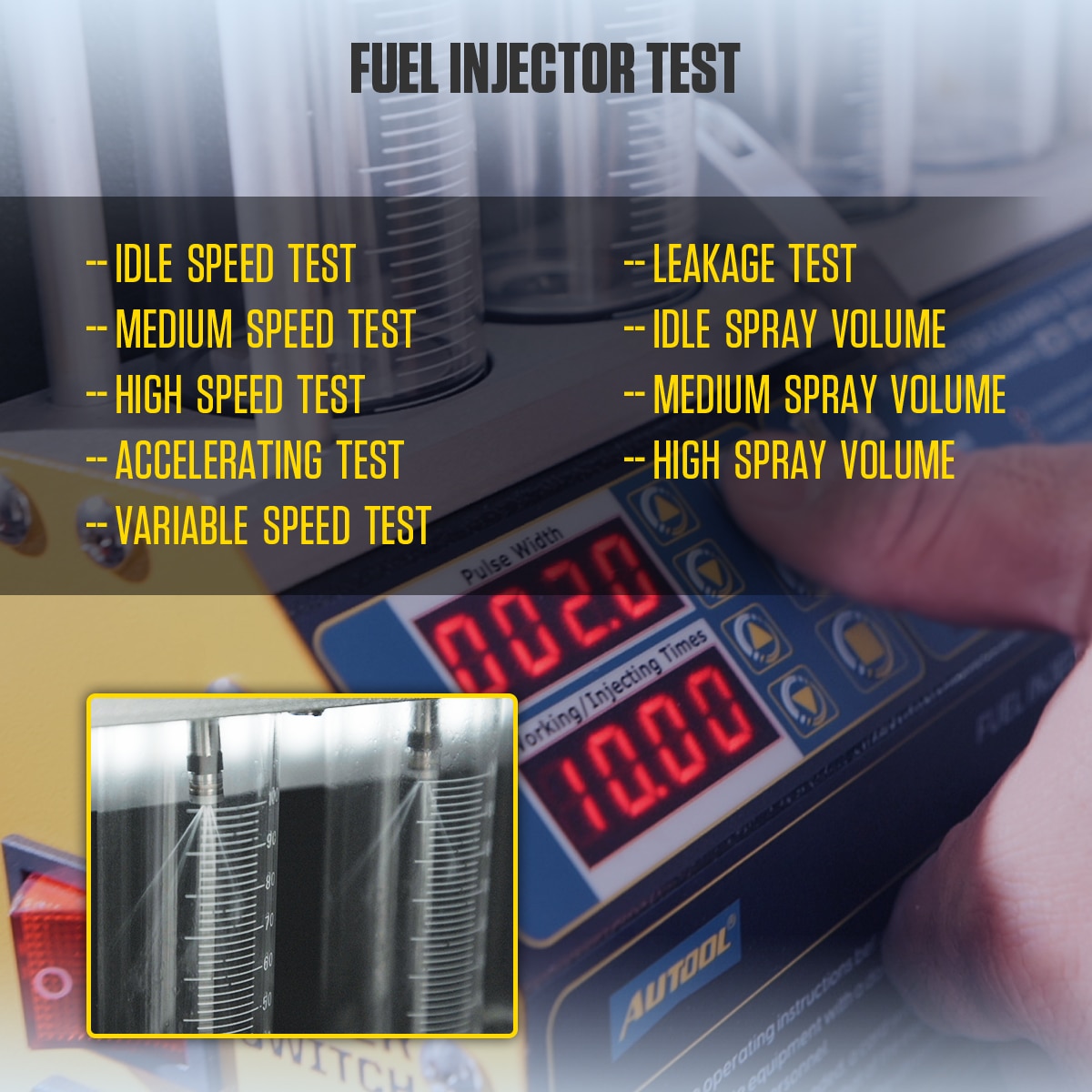

4.Performing leak test, spray pattern, and flow rate testing on flow bench.The injectors are now returned to the flow bench for retesting of all functions.

A Cleanning petrol injector with ultrasonic

B Cleanning spark plug.Put spark plug into cleaning tank ,input clean fluid and begin clean

C Testing injector injection in different situation, check leaking and blocking

D Cleanning injector without disassembly (need extra accessory and extra fee,choose by yourself)

E Cleanning throttle valve without disassembly. (need extra accessory and extra fee,choose by yourself)

F Cleanning and test motorcycle injector,testing function for HONDA YAMAHA SUZUKI SANYANG injectors only, (need extra accessory and extra fee,choose by yourself)

1pc* AUTOOL CT160 Fuel injector diagnostic and cleaning Cleaner Machine main unit

1pc*Refilling funnel

1pc* Ultrasonic leaning stand

1pc*Testing pad

2pc* Oil drain valve

1pc* Lock pole

1pc*Lock nut

4pc* Extended plug

4pc* Motorcycle top oil inlet connectorⅠφ10mm

4pc* Motorcycle top oil inlet connectorⅡφ11mm

4pc* Motorcycle top oil inlet connectorⅢφ10.6mm

4pc* Car top oil inlet connectorⅢφ10.6mm&13.4mm

3pc* Plug

1pc* Signal wire

4pc* Adapter cable

1pc* Oil rail

1pc* User manual

1. No response at boot

Check whether the fuse on the bottom of the right side of the machine is damaged. If it is damaged, please replace the fuse (AC 250V/5A).

2. Oil leakage at the oil separator assembly

Oil leakage at the oil separator, please check whether the installed “O” ring is matched, and check whether it is deformed or damaged. If it is not matched or damaged, please replace it;The two black adjusting screws should not be too tight, too tight will also cause oil leakage of the oil separator.

3. The oil pressure drops slowly

The oil pressure cannot drop to zero within 1 to 2 minutes, and you can use the hex wrench to adjust the relief valve counterclockwise.

4. The buzzer sounds long without oil pressure

The machine has a lack of oil alarm function. When the liquid level in the oil tank is insufficient, a sound will be emitted, and the oil pump and fuel injection nozzle will be automatically turned off and returned to stop later.In the state, the prompt sound will be closed automatically after adding enough cleaning fluid. At this time, you must press the [Run] key to restart the oil pump.

5. Must be pressed 'Drain key' twice to drain test solution completely

The solenoid valve of the machine has an automatic shut-off function within 15 seconds; more liquid in the glass tube may require multiple drains.

6. The amount of cleaning and test solution added

When adding cleaning fluid, the cleaning fluid in the ultrasonic box should not exceed the connection port of the fuel injection nozzle; when adding test fluid, the testing fluid should not exceed two-thirds of the glass tube level display.

7.Problems with cleaning and testing 4 injectors

there is a short circuit of the machine, which causes the protection of the machine to restart.It may be that the resistance value of the fuel injector is too low or there is a problem with the fuel injector. You need to find the problematic nozzle and replace it with another normal nozzle for cleaning. If there is no problem with the fuel injector, one of the pulse lines is damaged. There are 6pcs impulse lines, and each impulse line needs to be tested separately. If all 6pcs pulse lines can be used normally, this is the problem of the fuel nozzle.